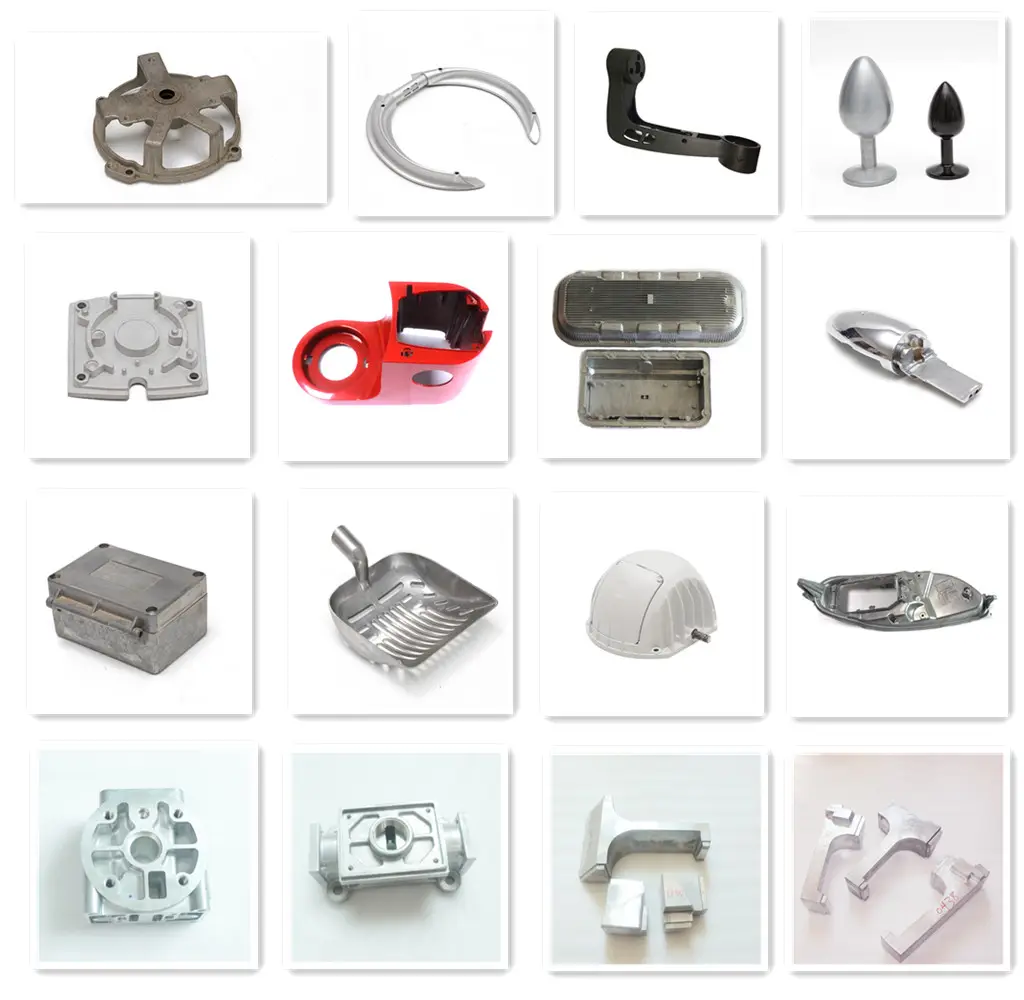

China Foundry Manufacturers Precision Custom OEM Cast Iron Zinc Metal Aluminum Die Casting Parts Services Die Cast Aluminum

Product Overview – Die Casting Parts Service

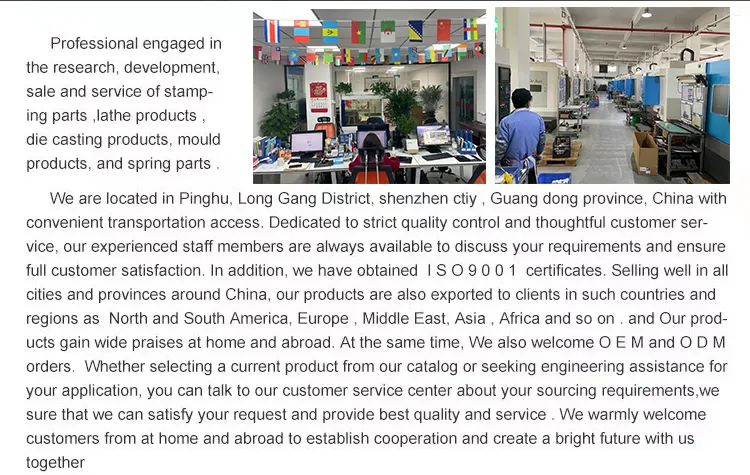

Shenzhen Huarui Century Technology Co., Ltd. is a professional manufacturer dedicated to providing high-precision die casting parts services for a wide range of industries. As one of the trusted China foundry manufacturers, we specialize in precision custom OEM cast iron parts, zinc alloy metal components, and aluminum die casting parts that meet the most demanding global standards.

With years of experience in die casting manufacturing, we integrate design, production, and inspection into one seamless process. Our products are widely used in automotive systems, industrial equipment, consumer electronics, and lighting housings. The die casting parts service we provide ensures parts with consistent quality, accurate dimensions, and superior surface finishes.

Key Product Highlights:

Comprehensive Material Support – Aluminum, zinc, and magnesium alloys are available, each offering unique performance characteristics suitable for lightweight, high-strength, or decorative applications.

Precision and Consistency – Advanced inspection tools and automated casting equipment guarantee high dimensional accuracy and stable mechanical properties.

Excellent Durability – Every die cast part provides superior resistance to wear, heat, and corrosion, ensuring a long service life in tough environments.

Custom OEM Capability – Our engineering team offers full customization support, including 3D modeling, mold design, and optimized process planning for each customer’s unique needs.

Product Advantages

One-stop Die Casting Solution from Design to Finished Parts

Shenzhen Huarui Century Technology Co., Ltd. offers a complete die casting parts service covering the entire production process—from mold design, tooling development, casting, CNC machining, to surface finishing. This one-stop solution eliminates communication barriers between suppliers, improves production efficiency, and ensures consistent quality control. Our integrated system allows for shorter production cycles and faster delivery, providing customers with a highly cost-effective and efficient production experience.

High-Precision Mold Manufacturing and Automated Equipment

We employ advanced CNC machining centers, EDM systems, and high-tonnage automated die casting machines to achieve exceptional precision in every mold and product. Automated injection systems ensure even metal flow and reduce defects such as porosity or shrinkage. With robotic trimming, automatic cooling, and precise temperature control, we guarantee consistent production quality and smoother surfaces. These technologies together ensure each part achieves perfect dimensional consistency and appearance.

Multi-Alloy Casting Capability

Our die casting parts service supports a wide selection of alloys including aluminum, zinc, and magnesium, meeting the demands of diverse applications. Aluminum die casting offers excellent strength-to-weight ratio and heat dissipation, zinc die casting provides outstanding dimensional stability and fine details, while magnesium die casting offers extreme lightness combined with high mechanical strength. This versatility allows us to supply precision components for various industries—automotive engine housings, motor enclosures, electronics frames, and smart lighting systems.

Stringent Quality Control and International Standards Compliance

Every process at Shenzhen Huarui Century follows strict ISO9001 quality management standards. We implement full-process inspection systems covering raw material testing, in-process dimensional checks, and final surface evaluations. Our factory is equipped with advanced measurement and inspection tools such as CMM (Coordinate Measuring Machine), hardness testers, and surface roughness analyzers. This ensures each batch of die casting parts meets international standards for reliability, accuracy, and appearance.

Efficient Production and Global Supply Capability

Our factory operates multiple automated die casting lines capable of handling both small and large-scale production. With optimized workflow and lean manufacturing management, we reduce material waste and improve overall production yield. Huarui Century serves global clients from Asia, Europe, and North America, providing competitive pricing, on-time delivery, and responsive after-sales support.

Production Process

Mold Design and Simulation

The process begins with precision mold design using CAD/CAM and casting simulation software. Flow analysis, cooling path optimization, and shrinkage prediction ensure molds perform efficiently and deliver stable, defect-free products.

Die Casting and Metal Injection

Molten metal is injected into the mold cavity under controlled temperature and high pressure. Advanced automatic die casting machines ensure smooth filling, rapid cooling, and fine-grained microstructure, resulting in high-density and strong parts.

CNC Machining and Surface Finishing

After casting, each part undergoes CNC milling, drilling, tapping, and polishing to achieve tight tolerances. Depending on client requirements, we offer various surface treatments including anodizing, powder coating, electroplating, painting, and polishing, which enhance corrosion resistance and improve appearance.

Quality Inspection and Assembly

Each component is subjected to multiple quality checks including visual inspection, dimensional verification, and mechanical performance testing. Finished parts can be assembled or packaged according to customer specifications to ensure immediate use upon delivery.

Frequently Asked Questions (FAQ)

Q1: What materials do you support for die casting?

We handle aluminum, zinc, and magnesium alloys, and can recommend the most suitable material depending on mechanical strength, appearance, and application environment.

Q2: Do you offer OEM or ODM customization?

Yes. We provide full OEM/ODM customization. Clients can send us 2D drawings or 3D models, and we will handle everything from mold design, casting, machining, to surface treatment.

Q3: Which industries use your die casting parts?

Our die casting parts services are widely used in automotive manufacturing, communication devices, electronics, medical equipment, robotics, lighting systems, and industrial machinery.

Q4: How do you ensure quality consistency?

All processes follow ISO quality control protocols. Each production batch is tested with advanced measuring tools to guarantee precision, durability, and surface perfection.

Q5: What is your standard lead time?

Lead time depends on mold complexity and production volume. Typically, new mold development takes 20–35 days, while mass production can be arranged immediately after sample approval.

Why Choose Shenzhen Huarui Century Technology Co., Ltd.

- Over 15 years of die casting manufacturing experience.

- Advanced CNC and automated die casting equipment.

- Support for multiple materials and custom solutions.

- Strict quality control aligned with ISO and RoHS standards.

- Efficient one-stop service from design to delivery.

Shenzhen Huarui Century Technology Co., Ltd. continues to expand its capabilities to meet global customers’ growing demand for precision die casting parts services. We are committed to innovation, quality excellence, and customer satisfaction.

Contact Us

If you are searching for a reliable China foundry manufacturer offering professional die casting parts services, Shenzhen Huarui Century Technology Co., Ltd. is your trusted partner.

Send us your inquiry today for a free quotation and technical consultation. Our professional engineers will help you design, optimize, and manufacture high-quality die cast aluminum, zinc, or cast iron parts tailored to your project requirements.

Let us help your business achieve greater efficiency and competitive advantage with our advanced die casting solutions.