Custom OEM Brass Sand Casting Services for Decorative and Industrial Metal Parts

Discover the perfect blend of classic aesthetics and modern engineering with our professional brass sand casting services. We specialize in producing high-quality, custom brass alloy components using the versatile sand casting process, ideal for both intricate decorative pieces and robust industrial parts. Our comprehensive in-house capabilities include advanced surface finishes like mirror polishing, electroplating, and powder coating, ensuring your parts meet exact aesthetic and functional specifications. Compliant with ISO9001, RoHS, and REACH standards, we are a reliable manufacturer offering end-to-end solutions from prototype to production for applications in architecture, furniture, marine, and machinery. Partner with us to bring your designs to life with durability and elegance.

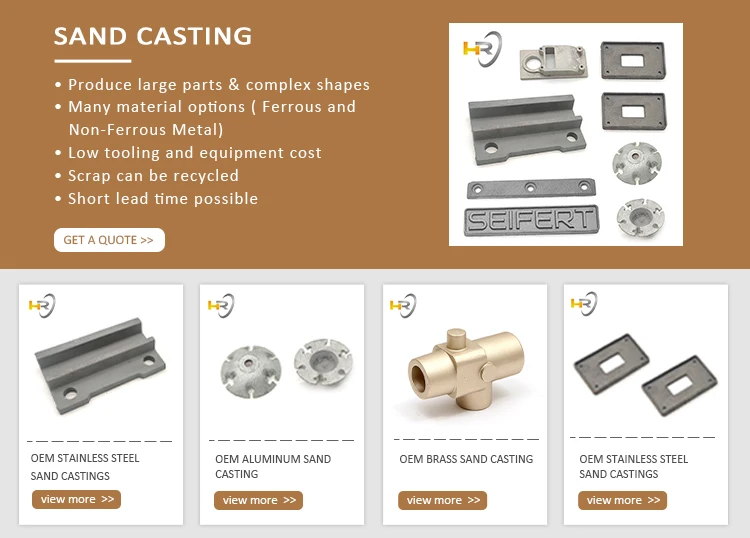

Product Description |

Oem sand casting parts |

Material |

Grey Iron, Ductile Iron, Steel, Stainless Steel, Aluminum, Brass, Bronze. |

Surface Treatment |

Polishing, sand blasting, heat treatment, painting, powder coating, anodizing,electroplating, Chrome plating, mirror polishing. |

Standard |

ISO9001,epr,lso14001,RoHS,REACH,etc. |

Size |

1.According to your 2D, 3D Drawing. 2.As per the customer’s samples. |

Payment terms |

T/T, L/C, Money Gram, PayPal, Crash, Western Union. |

application |

All kinds of aluminum casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on. |

The Art and Engineering of Brass: Your Premier Sand Casting Partner

In the realm of manufacturing, few materials marry timeless appeal with functional performance like brass. For industries where aesthetics, durability, and corrosion resistance are paramount, finding a reliable source for custom brass components is a critical business decision. This is where our specialized brass sand casting service excels. We are dedicated to transforming your concepts into tangible, high-integrity brass parts that serve as both the functional backbone and the decorative highlight of your products. More than just a supplier, we operate as an extension of your team, committed to delivering precision, quality, and a collaborative partnership that spans from initial design to final delivery.

Why Brass? The Unmatched Material for Demanding Applications

The choice of material is the first and most crucial step in any manufacturing project. Brass, a copper-zinc alloy, stands out for its unique combination of properties that make it a favorite across diverse sectors. It offers excellent machinability and castability, allowing for the production of complex shapes with fine details through the sand casting process. Beyond its workability, brass boasts superior corrosion resistance, making it ideal for marine hardware, plumbing fittings, and outdoor architectural elements. Its inherent antimicrobial properties add value for medical and sanitary applications. Furthermore, brass possesses a natural, warm luster that can be polished to a brilliant mirror finish or treated to achieve various antique and modern looks, providing unparalleled aesthetic versatility for furniture, décor, and luxury fittings. Our deep understanding of brass alloys ensures we help you select the optimal material for strength, appearance, and cost-efficiency.

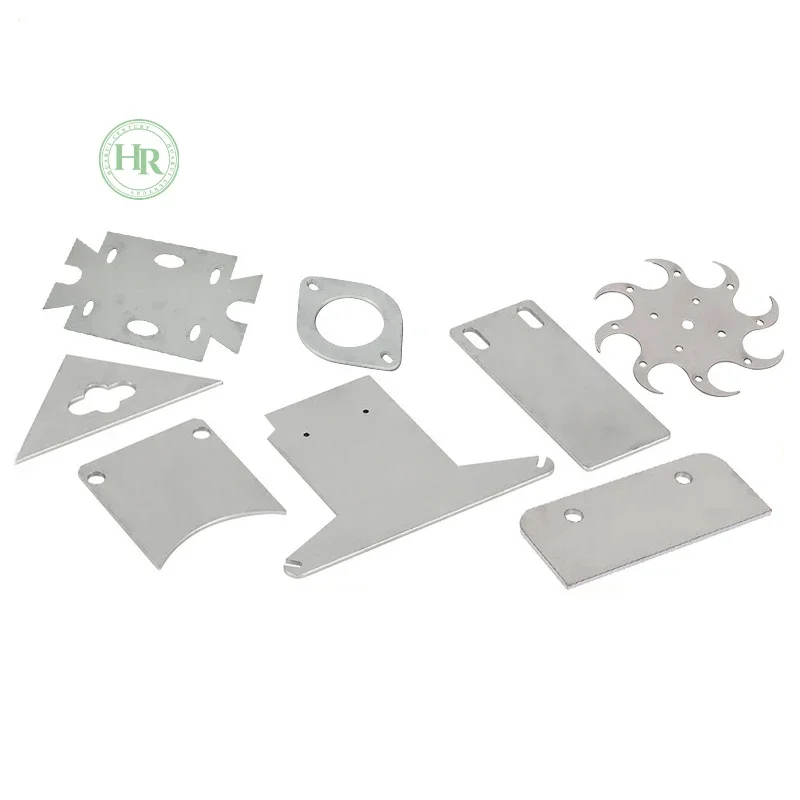

Mastering Sand Casting: Flexibility for Complex and Custom Designs

The sand casting process is the ideal method to unlock the full potential of brass for your custom parts. Unlike other high-pressure methods, sand casting offers exceptional flexibility, making it perfectly suited for low to medium production volumes, large-sized components, and parts with intricate internal geometries or complex cores. The process involves creating a mold from a sand mixture that perfectly replicates your part's shape, offering significant cost advantages in tooling compared to permanent mold processes. This flexibility is a cornerstone of our service, allowing us to accommodate highly customized, one-of-a-kind designs or prototype runs without prohibitive upfront investments. Whether you need a single, ornate architectural medallion or a batch of specialized industrial valve bodies, our mastery of brass sand casting ensures your design is realized with fidelity and structural soundness.

From Rough Casting to Refined Masterpiece: Our Surface Finishing Expertise

The journey of a brass casting is completed by its surface. We provide a comprehensive suite of finishing services that enhance both the performance and visual appeal of your parts. For a sleek, modern, and hygienic surface, we offer precision polishing, capable of achieving a stunning mirror finish that highlights brass's natural beauty. Electroplating options, such as chrome or nickel plating, provide a hard, durable, and tarnish-resistant surface with a bright or satin sheen. For applications requiring color, extra corrosion protection, or specific textures, our powder coating services offer a vast palette of durable, weather-resistant finishes. We also specialize in patina and antique finishes that give brass parts a classic, time-worn character for decorative projects. This in-house, end-to-end capability means your brass sand casting parts arrive fully finished, ready for installation or assembly, saving you time and coordinating multiple vendors.

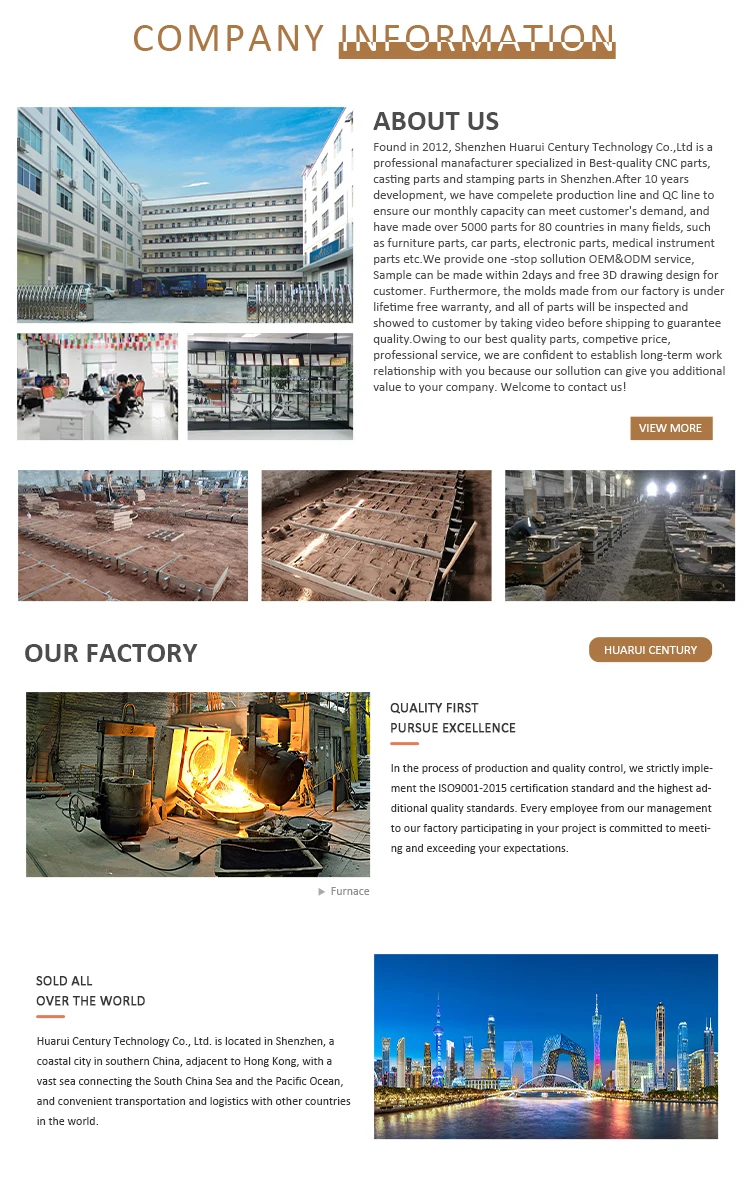

Commitment to Quality: Precision and Compliance You Can Trust

Every brass sand casting part we produce is underpinned by a rigorous quality management system. Our commitment begins with precise pattern-making and extends through every stage of the sand casting process, including meticulous mold assembly, controlled pouring, and careful shakeout. We employ thorough inspection protocols, utilizing dimensional checks and visual inspections to ensure each part conforms to your specifications. As a professional manufacturer, our operations are aligned with international standards, including ISO 9001 for quality management. We strictly adhere to material safety directives such as RoHS and REACH, ensuring our brass castings are compliant for global markets, particularly the European Union. This dedication to controlled processes and regulatory compliance provides you with the assurance that you are receiving safe, reliable, and high-quality components.

Versatile Applications: Where Our Brass Castings Excel

The components produced by our brass sand casting service are engineered to perform and impress across a wide spectrum of industries. In architecture and construction, they are the elegant door handles, sturdy railings, decorative light fixtures, and historic restoration elements that define a space. For the furniture and interior design sector, we produce luxurious hardware, custom table bases, and unique decorative accents that elevate product value. Industrially, our brass castings serve as reliable, corrosion-resistant parts for marine hardware, pump and valve bodies, and non-sparking tools for hazardous environments. We also cater to niche creative projects, such as musical instrument components, awards, and custom machinery parts. This broad applicability is a testament to the versatility of both the brass material and our sand casting expertise, allowing us to provide tailored solutions no matter your field.

Initiating Your Custom Brass Casting Project: A Streamlined Partnership

Beginning a project with us is designed to be straightforward and transparent. We accept your design inputs in all common formats, including 2D drawings, 3D models (STEP, IGES, Solidworks), or physical samples. Our engineering team will then review your design for manufacturability, offering expert advice to optimize the part for the sand casting process, potentially improving quality and reducing cost. We believe in clear communication and provide detailed quotations outlining scope, timeline, and pricing.

We are a trusted manufacturing partner based in China, focused on building lasting relationships through reliability and exceptional service. Our sales and technical support teams are dedicated to understanding your specific needs and delivering brass sand casting solutions that enhance your product's market appeal and functionality. We invite you to experience the advantage of working with a specialized foundry. Contact us today to discuss your custom brass part requirements, request a quote, and see how our high-quality castings can contribute to your next successful project.