Precision Sand, Die and Investment Casting for Multi-Metal Industrial OEM Parts

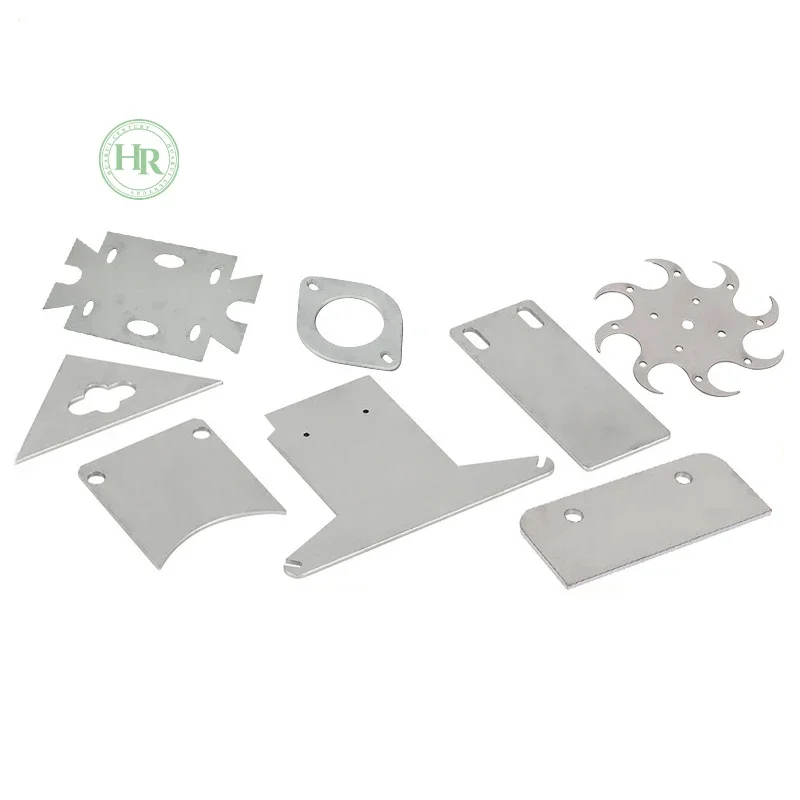

Expertly engineered metal casting solutions encompassing die casting, sand casting, and precision lost-wax investment casting. We process a comprehensive range of materials including aluminum alloys (ADC12, A356, A380), zinc alloys, magnesium, stainless steel, and brass to produce high-quality, durable components. Ideal for applications in furniture, industrial fittings, construction, automotive, and medical devices. Our services support full customization from prototype to mass production, backed by ISO 9001, ISO 14001, REACH, and RoHS compliance.

Processing technology |

Die casting parts, sand casting parts, Investment casting parts |

Mold Material |

Aluminum,SKD61,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Material |

Aluminum:ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized . Zinc: ZA3#, ZA5#, ZA8# or customized . Magnesium: AZ91D, AM60B or customized . |

Surface Treatment |

Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

Drawing format |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

Certificate |

iso9001, iso14001, REACH, ROHS |

Application |

furniture,Industry fittings and Construction and Decoration,etc. |

HUARUI

Are you looking for high-quality metal casting parts that are reliable and durable? Look no further than Huarui’s range of iron, zinc, metal, stainless steel, aluminum alloy, brass, sand casting, precision lost wax investment casting part, and die-cast services.

Specializes in designing and manufacturing metal casting components with precision and expertise. Their range of products includes various types of metal castings that focus on industries that are various applications.

Well suited for applications that want durability and strength such as for example construction equipment, automotive parts, and machinery is agricultural. Meanwhile, their zinc casting parts are perfect for tiny and components that are intricate as fixtures, hinges, and clips.

Produced from stainless steel or aluminum alloy are your very best bet if you want components which are resistant to corrosion. These materials are utilized in industries such as marine, food processing, and equipment is medical to their anti-corrosive properties.

Can be obtained in applications such as plumbing, valve components, and instruments that are musical. They are known for their excellent conductivity is thermal ductility, and malleability.

Offers sand casting services, that will be a method is popular casting big and heavy parts such as engine blocks, valves, and pump housings. This procedure involves employing a mildew made of sand to generate the desired shape.

A complex and procedure is precise works on the wax pattern to produce a mold. This will be a method is popular creating intricate and delicate components such as for instance jewelry, aerospace components, and dental implants.

Ideal for creating little and forms which are complex high precision. This procedure involves injecting molten steel into a mold under high pressure and it is commonly used in automotive, electronic devices, and appliance manufacturing.

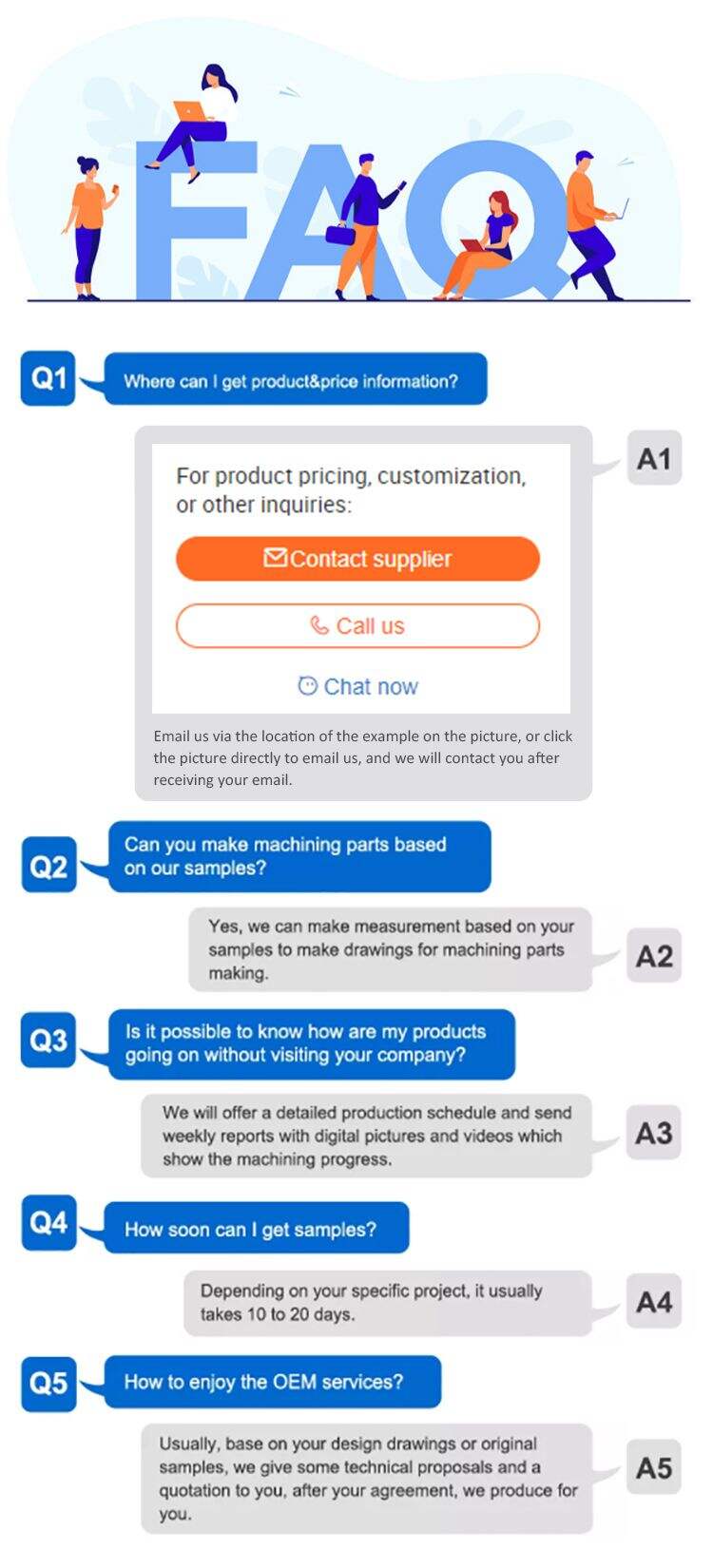

With Huarui, you can be assured of quality and reliable metal casting parts that meet your specific requirements. Whether you need parts for high-temperature applications, corrosive environments, or high precision machinery, Huarui has got you covered. Get in touch with Huarui today and experience their exceptional products and services.

Unlock Your Vision with Expert Metal Casting Solutions

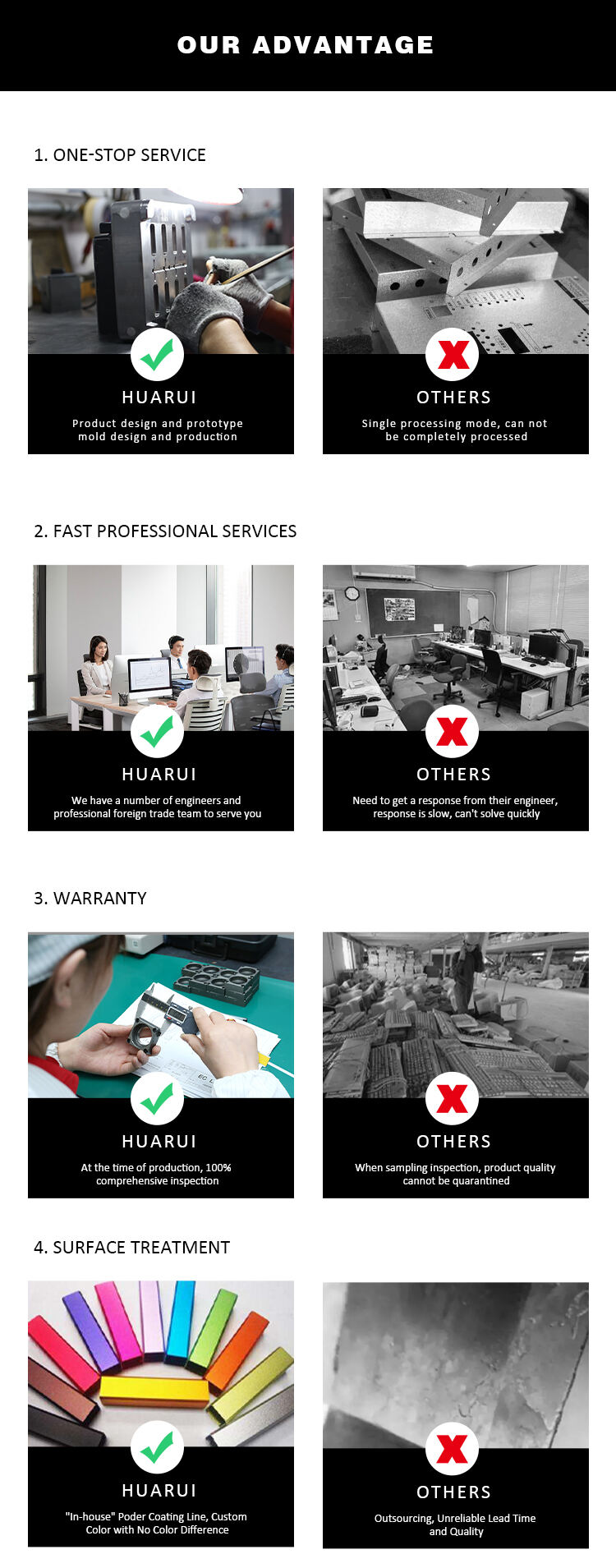

In the world of manufacturing, the quality of a component begins with the precision and capability of its production process. For industries where strength, complexity, and reliability are non-negotiable—from automotive and aerospace to medical devices and industrial machinery—choosing the right metal casting partner is a critical decision. This is where our expertise becomes your advantage. We are dedicated to transforming raw materials into high-performance parts through advanced casting technologies. Our mission is to provide a comprehensive, one-stop solution for all your metal casting needs, ensuring every component we produce not only meets but exceeds the rigorous demands of its application. By integrating extensive engineering knowledge with state-of-the-art production and stringent quality control, we deliver metal casting parts that form the reliable backbone of products worldwide.

A Trio of Advanced Processes for Every Manufacturing Challenge

Our strength lies in our ability to match the perfect casting process to your unique design and performance requirements. We don't believe in a one-size-fits-all approach. Instead, we offer three core metal casting services, each with distinct advantages for different part geometries, volumes, and material needs.

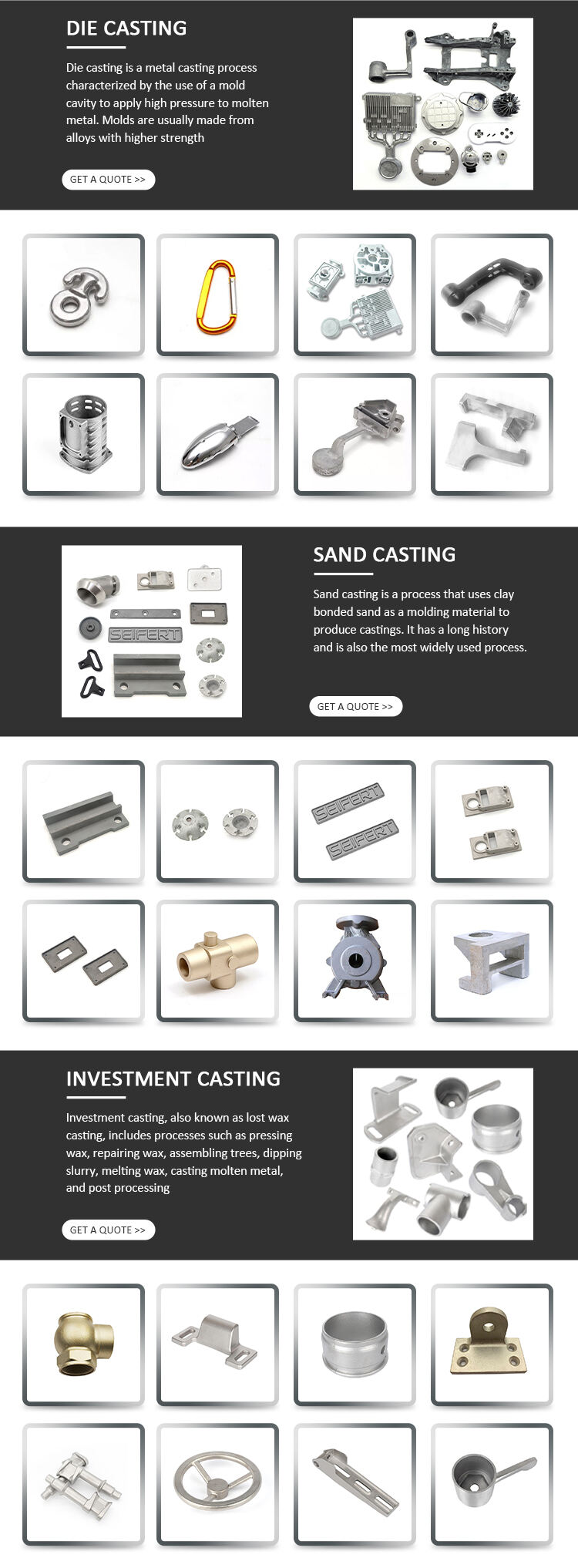

High-Pressure Die Casting: Precision at Speed for Complex Geometries

When your project calls for high-volume production of components with intricate details, thin walls, and excellent dimensional consistency, our die casting services are the ideal choice. This process involves injecting molten metal under high pressure into a precision steel mold. It is exceptionally efficient for creating complex, net-shape parts with superior surface finish, minimizing the need for secondary machining. We commonly utilize aluminum alloys like ADC12, A380 and zinc alloys in our die casting operations, producing lightweight yet strong components essential for the automotive, electronics, and consumer appliance industries. From intricate brackets and heat sinks to robust housings, our die casting capability ensures repeatable quality and cost-effectiveness for large runs.

Robust Sand Casting: The Foundation for Large and Heavy-Duty Parts

For larger, heavier components or when prototyping and lower-volume production is required, our sand casting process offers unparalleled flexibility. This versatile method uses a mold formed from compacted sand, allowing for the production of massive parts that would be impractical or too costly with other metal casting techniques. It is exceptionally well-suited for parts like machine bases, large valves, pump housings, and structural components for construction and decoration. The sand casting process can accommodate a wider range of ferrous and non-ferrous metals, making it a cornerstone for the industrial machinery, heavy equipment, and construction sectors. Our expertise ensures these large-scale metal casting parts possess the structural integrity and durability required for the most demanding environments.

Lost-Wax Investment Casting: Unmatched Detail for the Most Demanding Applications

When absolute precision, complex internal features, and superb surface quality are paramount, our investment casting (lost-wax) services deliver exceptional results. This intricate process begins with a wax pattern of the part, which is then coated in a ceramic shell to form the mold. Once the wax is melted away, molten metal is poured in. This technique is renowned for producing parts with extremely fine details, tight tolerances, and smooth surfaces, often requiring little to no finish machining. Investment casting is the preferred method for creating critical components in aerospace, medical (such as surgical instrument parts), and high-end industrial applications. It allows for the use of challenging alloys like stainless steel and is ideal for producing metal casting parts that are both geometrically complex and structurally sound.

Material Mastery: Engineering the Right Properties for Your Part

The performance of a cast component is defined as much by its material as by its shape. We offer an extensive selection of alloys, enabling us to engineer metal casting parts with precisely the characteristics your application demands. Our capabilities include processing aluminum alloys such as ADC12, A360, A356, and A380 for an optimal balance of strength and lightweight properties. We work with zinc alloys like ZA-3, ZA-5, and ZA-8 for excellent dimensional stability and thin-wall capabilities. For the lightest structural components, magnesium alloys like AZ91D are available. We also cast brass for its machinability and corrosion resistance, alongside various grades of stainless steel for maximum strength and resistance to harsh environments. Our engineering team will collaborate with you to select the optimal material, whether it's a standard alloy or a customized specification, to ensure your metal casting parts achieve the desired mechanical properties, durability, and cost profile for applications ranging from furniture hardware to critical industrial fittings.

Finishing Touches: Comprehensive Surface Treatment for Enhanced Performance

The journey of a metal casting part does not end at the mold. The right surface treatment is crucial for enhancing functionality, improving aesthetics, and providing extra protection. We offer a complete range of finishing options to meet your specific requirements. For a standard, as-cast look with minimal processing, we provide a mill-finished surface. When enhanced durability and a uniform, decorative color are needed, our powder coating services deliver a tough, corrosion-resistant layer. For applications requiring a smooth, reflective, or sanitary surface, we offer precision polishing. We also provide brushing to achieve a consistent satin or directional grain aesthetic. This comprehensive suite of finishing capabilities ensures that every metal casting part we deliver is not only functionally precise but also finished to the highest standard, ready for its end-use in construction, decorative, industrial, or consumer applications.

Our Unwavering Commitment to Quality and Precision

Quality is not merely a department; it is the foundational principle embedded in every stage of our operation. Our commitment is validated by our ISO 9001:2015 and ISO 14001 certifications, which govern our integrated management system, alongside our adherence to REACH and RoHS directives. Our quality assurance begins at the design review stage, where our engineers analyze your drawings—accepted in all major formats like STEP, IGES, and Solidworks—for manufacturability. We employ precision molds crafted from premium steels like H13, 718, and SKD61 to ensure longevity and dimensional accuracy. Throughout the metal casting process, from molten metal preparation to finishing, critical parameters are continuously monitored. Every batch of metal casting parts undergoes rigorous inspections, including dimensional checks, visual and surface examinations, and material verification. This meticulous, end-to-end control is how we consistently deliver metal casting parts that achieve a remarkable quality standard, giving you complete confidence in every component you receive.

Empowering Industries with Critical Components

Our metal casting services are integral to innovation and reliability across diverse sectors. In the automotive industry, we produce lightweight aluminum housings and strong zinc brackets. In medical technology and dental equipment, we craft precise, biocompatible stainless steel instrument components via investment casting. For industrial equipment and machinery, we supply durable iron and steel parts through sand casting that withstand extreme stress and wear, perfectly suited for heavy-duty fittings. The furniture and architectural decoration sectors benefit from our ability to cast beautifully finished brass, aluminum, and zinc components for both structural and aesthetic purposes. The electronics industry relies on our die casting for finely detailed magnesium and aluminum enclosures that provide shielding and heat dissipation. Each industry has unique standards, and our deep application knowledge ensures the metal casting parts we supply are perfectly engineered for their end-use environment, whether it requires corrosion resistance for construction or high precision for medical devices.

Why Choose Us as Your Casting Partner

Selecting us means partnering with a manufacturer defined by more than just machinery. It is a partnership built on deep technical expertise in die casting, sand casting, and investment casting processes. We offer a flexible production approach that welcomes projects from single prototypes to high-volume runs, supporting trial orders with minimal MOQ. Our comprehensive quality control and transparent processes provide you with peace of mind. We are more than a supplier; we are an extension of your engineering team, committed to delivering high-quality, customized solutions that drive your success. With our extensive material options, from aluminum and zinc to stainless steel and brass, and our full suite of surface treatments, we provide a true end-to-end metal casting service. Contact us today to discuss your project and experience the difference that a true expert in metal casting can make for your furniture, industrial, construction, or technological applications.