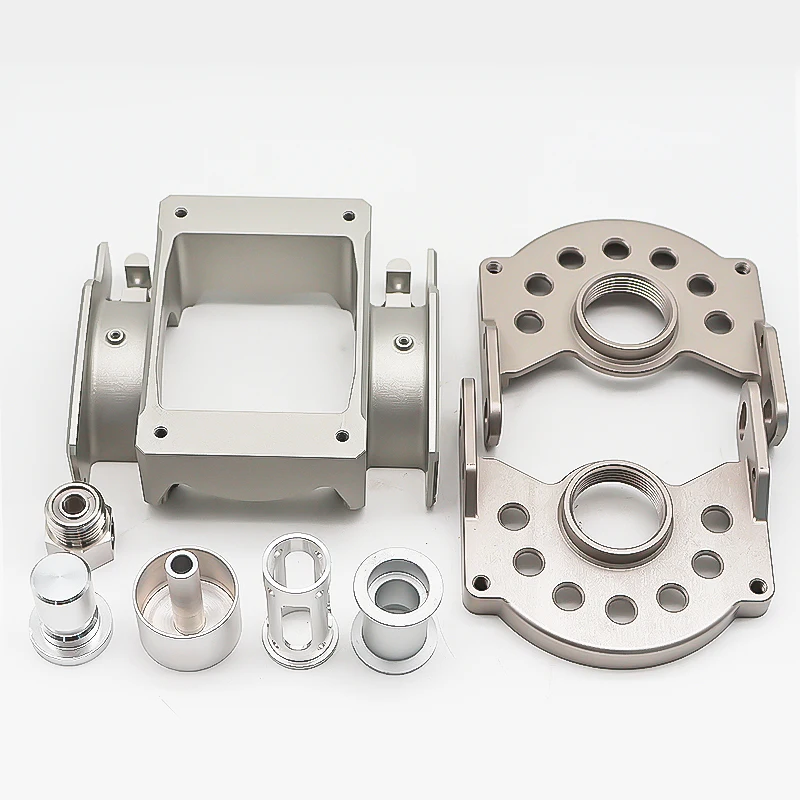

Custom 5-Axis CNC Machining and Anodizing Services for Precision Aluminum Parts

Elevate your product with our integrated manufacturing solution that combines high-precision 5-axis CNC machining with professional anodizing. We specialize in producing custom aluminum parts where exceptional dimensional accuracy (±0.01mm) meets enhanced surface performance. Our in-house, seamless process from machining to anodizing ensures superior corrosion resistance, increased wear hardness, and premium aesthetic finishes. Ideal for aerospace, medical, and high-end electronics, we deliver finished components ready for demanding applications.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

Where Precision Meets Performance: The Integrated Solution for Superior Aluminum Components

In the realm of high-stakes manufacturing, a component’s true value is realized not just by how precisely it is cut, but by how expertly it is finished. For aluminum parts destined for challenging environments, anodizing isn't merely an afterthought—it’s a critical performance upgrade. Yet, sourcing precision machining and quality anodizing from separate vendors introduces risk, inconsistency, and delay. Shenzhen Huarui Century Technology redefines this paradigm. We offer a unified service where advanced 5-axis CNC machining and controlled anodizing are orchestrated under one roof. Our mission is to deliver not just machined aluminum parts, but fully realized, high-performance anodized aluminum components where geometry and surface integrity are guaranteed from start to finish. This integrated approach is the key to achieving reliability in the most demanding applications, from aerospace assemblies to surgical device housings.

Beyond Surface Deep: How Anodizing Transforms Aluminum into a Premium Material

To understand the value of our integrated service, one must first appreciate the transformative power of anodizing. This electrochemical process converts the aluminum surface into a durable, corrosion-resistant oxide layer. This layer is integral to the metal, not merely a coating, meaning it won’t chip or peel. The benefits are substantial: surface hardness can increase dramatically, making the part highly resistant to wear and abrasion. The porous nature of the anodic layer allows for deep, permanent dyeing in a vast spectrum of colors, satisfying both branding and functional coding needs. Furthermore, it provides excellent electrical insulation and improves paint and adhesive bonding. For any part facing environmental exposure, frequent handling, or stringent aesthetic requirements, specifying anodized aluminum parts is a strategic decision for long-term performance. Our service ensures this transformation is executed with scientific precision, tailored to your component’s exact duty cycle.

The Precision Link: Engineering for the Anodizing Process from the First Cut

The cornerstone of our value proposition is the meticulous synchronization between machining and anodizing. A critical technical nuance often overlooked is dimensional growth: during anodizing, the oxide layer grows, typically adding 0.008-0.012mm per surface. For a part holding a ±0.01mm tolerance, this is not negligible. Our engineers are experts in precision metal CNC machining with anodizing in mind. During the CAM programming phase, we proactively apply precise compensations to the 5-axis milling toolpaths, ensuring the final anodized aluminum part meets all dimensional specifications post-process. This foresight eliminates the all-too-common problem of parts becoming undersized after coating. Additionally, we optimize the machined surface finish to ensure the anodic layer forms uniformly, resulting in consistent color and texture. This deep, upfront process engineering is what separates our custom CNC machining services from a simple sequence of unrelated jobs, guaranteeing that the full potential of both precision machining and anodizing is achieved.

Seamless In-House Production: Your Guarantee of Consistency and Accountability

Choosing our integrated service means opting for simplicity, speed, and single-point responsibility. The journey for your parts is a continuous, controlled flow within our facility. After your design is validated and the precision CNC machining on our 5-axis centers is complete, the components move directly to our dedicated anodizing department—not to a third-party processor. This eliminates external shipping, requoting, and communication gaps. More importantly, it allows for integrated quality control. We perform inspections at multiple stages: verifying critical dimensions after machining with CMMs, checking the anodic film thickness and hardness, and conducting final audits for color consistency and surface integrity. This end-to-end control, backed by our ISO-certified quality management system and 100% QC inspection before delivery, provides a transparent and reliable chain of custody. You receive a comprehensive inspection report, affirming that your anodized aluminum parts meet all agreed mechanical and cosmetic standards.

Material and Finish Expertise: Tailoring the Solution to Your Application

Our collaboration extends to selecting the optimal aluminum alloy and anodizing specification for your needs. We advise on the best substrate—whether it’s 6061 for its excellent anodizing response, 7075 for high strength, or a casting alloy for complex geometries—to balance machinability and final performance. We then execute the precise type of anodizing required: clear anodizing for corrosion protection and a metallic look, color anodizing for branding, or hardcoat anodizing (Type III) for extreme abrasion resistance in industrial applications. This consultative approach ensures the materials and processes are aligned with the component’s functional life, whether it needs to withstand sterilization cycles in a medical setting, salt spray in marine applications, or daily wear in consumer electronics.

Why Partner with Us for Your Anodized Aluminum Components?

The decision to consolidate your supply chain with Shenzhen Huarui Century Technology offers tangible, competitive advantages:

Unmatched Process Integration:

Our decade of experience as an OEM and ODM manufacturer is built on mastering interconnected processes. We don’t just perform machining and anodizing; we engineer them to work together flawlessly, which is essential for producing reliable precision metal CNC machining parts.

Eliminated Supply Chain Risk:

By being your sole source, we assume complete accountability for the entire manufacturing process. This removes the finger-pointing that can occur between separate machining and coating suppliers, streamlining issue resolution and protecting your project timeline.

Accelerated Time-to-Market:

The internal handoff between our machining and anodizing teams is swift and efficient. This significantly reduces total lead time compared to managing multiple vendors, allowing you to move faster from prototype validation to volume production.

Assured Quality and Traceability:

With complete in-house control, we maintain strict oversight at every step. Our commitment to a 99.99% product qualification rate is applied across the entire manufacturing journey, giving you confidence in the consistency and quality of every batch of custom anodized aluminum parts you receive.

Applications Demanding the Integrated Advantage

Our service is specifically designed for industries where failure is not an option and appearance matters. We manufacture anodized aluminum parts for:

Aerospace & Defense: Lightweight brackets, housings, and instrumentation parts requiring high strength-to-weight ratios, corrosion resistance, and durability.

Medical & Dental Equipment: Surgical tool handles, device enclosures, and instrument trays that must withstand repeated sterilization, offer chemical resistance, and provide a clean, professional aesthetic.

High-End Consumer Electronics: Laptop chassis, camera bodies, and wearable device components that demand precise fit, premium feel, scratch resistance, and iconic color finishes.

Automation & Robotics: Guards, frames, and actuator components that need to maintain dimensional stability and resist wear in industrial environments while often incorporating color-coded safety elements.

Begin Your Project with a Unified Manufacturing Partner

Starting is straightforward. Contact us with your CAD model and performance requirements. Our engineering team will provide a detailed analysis and quotation that encompasses both 5-axis milling and anodizing services. We’ll guide you on design optimizations for manufacturability and finish selection. Upon approval, your project enters our integrated workflow, where you have one dedicated point of contact throughout. Experience the confidence that comes with a seamless, high-quality supply chain. Reach out today to discuss how our combined custom CNC machining and anodizing services can bring superior performance and finish to your next project.