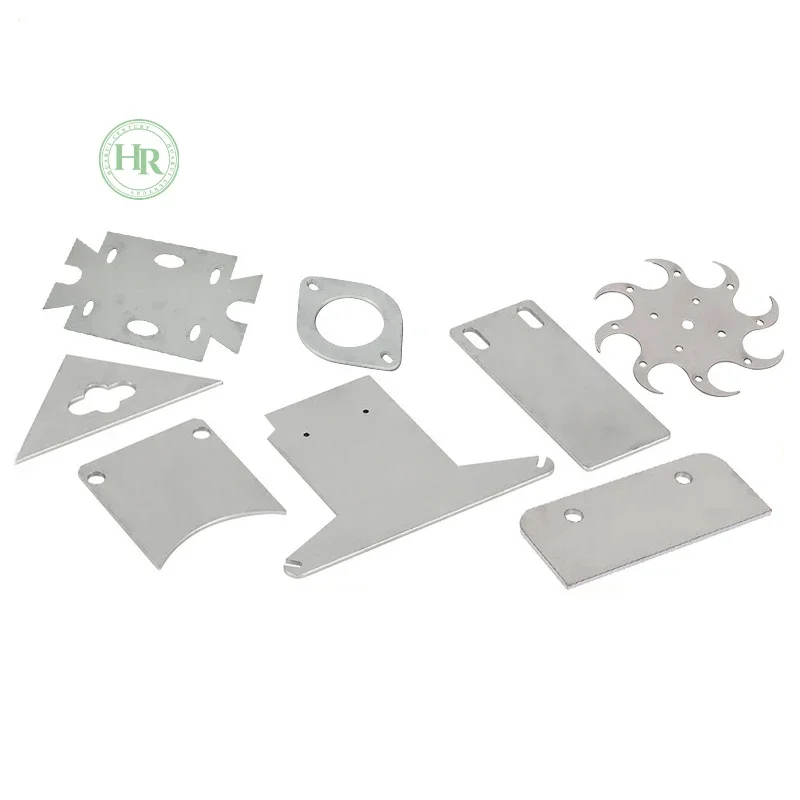

Custom OEM ADC12 Aluminum Alloy Die Casting Parts with Sand Blasting Anodizing Coating

Elevate your manufacturing with our high-performance custom die casting parts made from premium ADC12 aluminum alloy. Engineered for precision and durability, these components undergo specialized surface treatments including uniform mechanical sand blasting, protective anodizing, and durable powder coating to meet stringent aesthetic and functional demands. Ideal for demanding applications across automotive, aerospace, electronics, and industrial machinery sectors. As a reliable manufacturer, we provide comprehensive OEM solutions from design to finished part, ensuring superior quality, perfect fit, and enhanced longevity for your products.

Introducing, the Hot Sale Custom Aluminium Alloy ADC-12 Die Casting Parts from Huarui! These innovative mechanical sand blasting, anodizing, and powder coated casting parts are designed to meet all of your manufacturing needs with precision and durability.

Made from high-quality aluminium alloy ADC-12, these die casting parts are lightweight yet incredibly strong, making them the perfect choice for a wide range of applications. Whether you are in the automotive, aerospace, or electronics industry, these parts are sure to exceed your expectations.

The mechanical sand blasting process used in the manufacturing of these parts ensures a smooth and uniform surface finish, free from any imperfections or burrs. This not only enhances the appearance of the parts but also improves their overall performance and longevity.

Additionally, the anodizing treatment adds a protective layer to the surface of the parts, preventing corrosion and increasing their resistance to wear and tear. This makes these casting parts ideal for use in harsh environmental conditions or applications that require frequent cleaning.

For added durability and aesthetic appeal, these parts are also available in a range of powder coated finishes, allowing you to customize them to suit your specific needs and preferences. Whether you prefer a glossy, matte, or textured finish, the options are endless with Huarui's custom aluminium alloy casting parts.

Furthermore, the precision engineering and advanced technology used in the production of these parts guarantee a perfect fit and seamless integration into your manufacturing process. You can trust that these parts will deliver consistent performance and reliability, helping you streamline your production and improve your overall efficiency.

Huarui's Hot Sale Custom Aluminium Alloy ADC-12 Die Casting Parts are a must-have for any industry looking for high-quality, reliable, and customizable casting parts. Trust in Huarui's expertise and experience to provide you with the best solutions for all your manufacturing needs. Experience the difference with Huarui today

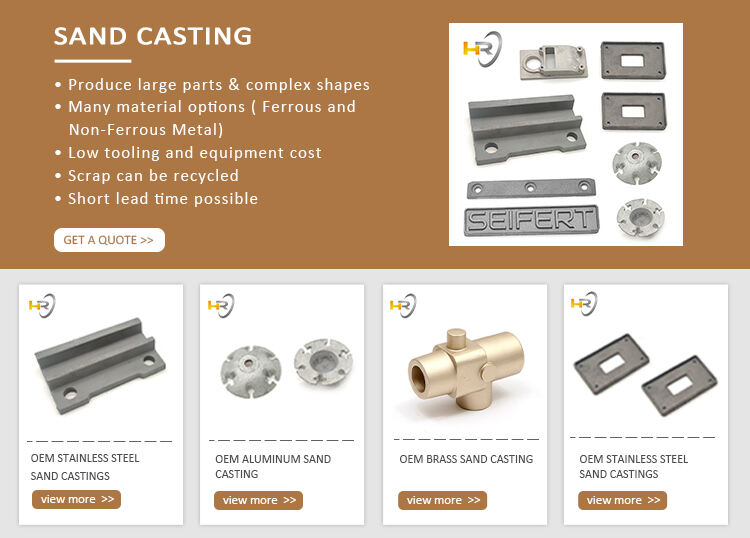

Product Description |

Oem sand casting parts |

Material |

Grey Iron, Ductile Iron, Steel, Stainless Steel, Aluminum, Brass, Bronze |

Surface Treatment |

Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing |

Standard |

ISO9001, EPR, lso14001, RoHS, REACH, etc |

Size |

1. According to your 2D, 3D Drawing 2. As per the customer’s samples |

Payment terms |

T/T, L/C, Money Gram, PayPal, Crash, Western Union |

application |

All kinds of aluminum casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on |

Precision Engineered: The ADC12 Aluminum Advantage

In an era where efficiency and performance are paramount, the choice of material forms the foundation of any superior component. For industries demanding an optimal balance of lightness and strength, ADC12 aluminum alloy stands as a material of choice for advanced die casting. This specific alloy is renowned within the manufacturing world for its exceptional castability, allowing it to flow smoothly into intricate molds to capture complex geometries with high dimensional accuracy. Beyond its formability, ADC12 provides excellent mechanical properties, including good strength and corrosion resistance, making it a reliable and cost-effective solution for high-volume production. Our expertise lies in harnessing the full potential of this alloy, transforming it into precision die casting parts that serve as critical, durable building blocks for innovative products across the globe. By choosing our ADC12 die casting service, you partner with a producer dedicated to material excellence and component reliability.

The High-Pressure Die Casting Process: Where Complexity Meets Efficiency

The true potential of ADC12 aluminum is unlocked through the high-pressure die casting process, a technique we have mastered to deliver consistency and quality. This method involves injecting molten aluminum under significant pressure into precision-engineered steel molds. This process is uniquely capable of producing parts with remarkably thin walls, intricate details, and excellent surface finishes at a rapid pace, making it exceptionally efficient for large-scale manufacturing runs. The result is a net-shape or near-net-shape component that minimizes the need for extensive secondary machining, reducing both waste and production time. Our commitment to this process is backed by advanced machinery and meticulous control over every parameter, from temperature to injection speed. This ensures that every batch of die casting parts we produce not only meets precise specifications but also exhibits the structural integrity required for demanding applications, from automotive engine brackets to sophisticated electronic enclosures.

Surface Enhancement: Tailored Finishes for Performance and Appeal

A superior die casting part is defined not just by its shape, but by its surface. We offer a suite of advanced finishing treatments designed to add functional durability and aesthetic value to our ADC12 aluminum die casting parts.

Mechanical Sand Blasting:

This process propels fine abrasives at high velocity to create a uniform, matte surface texture. It effectively removes minor imperfections, burrs, and tooling marks left from the casting process, ensuring a clean and consistent base. The resulting surface is not only visually appealing but also provides an ideal substrate for subsequent coatings, improving their adhesion and longevity.

Anodizing:

More than just a finish, anodizing is an electrochemical process that grows a thick, protective oxide layer on the aluminum surface. This layer is integral to the metal, making it exceptionally hard, resistant to corrosion, and highly durable against wear and abrasion. Anodizing also offers excellent thermal and electrical insulation properties. Available in a range of colors, including clear, black, and various hues, it provides both permanent protection and aesthetic customization for your die casting parts.

Powder Coating:

For applications requiring a robust, colorful, and textured shield, powder coating is the optimal choice. This dry-finishing process applies a layer of free-flowing powder electrostatically, which is then cured under heat to form a hard, continuous film. The coating is highly resistant to chipping, scratching, fading, and chemicals. We offer an extensive palette of colors and finishes—from glossy and matte to textured—allowing you to brand, color-code, or simply enhance the visual appeal and environmental resilience of your components.

Proven Applications: Driving Innovation Across Sectors

The versatility of our finished ADC12 die casting parts makes them indispensable across a spectrum of high-tech and demanding industries. In the automotive sector, their strength-to-weight ratio contributes to lightweighting efforts, making them ideal for engine components, transmission housings, and structural brackets, all while withstanding under-hood temperatures and vibrations. Aerospace applications benefit from the same lightweight durability for non-critical structural elements and instrumentation housings. Within electronics, these parts provide robust, heat-dissipating, and EMI-shielding enclosures for consumer devices, telecommunications equipment, and power systems. Furthermore, industrial machinery utilizes our castings for durable housings, gears, and frames that endure operational stress. Each industry's unique challenges are met with our tailored approach to die casting, ensuring the final part performs reliably in its specific environment, proving that a well-manufactured component is key to product success.

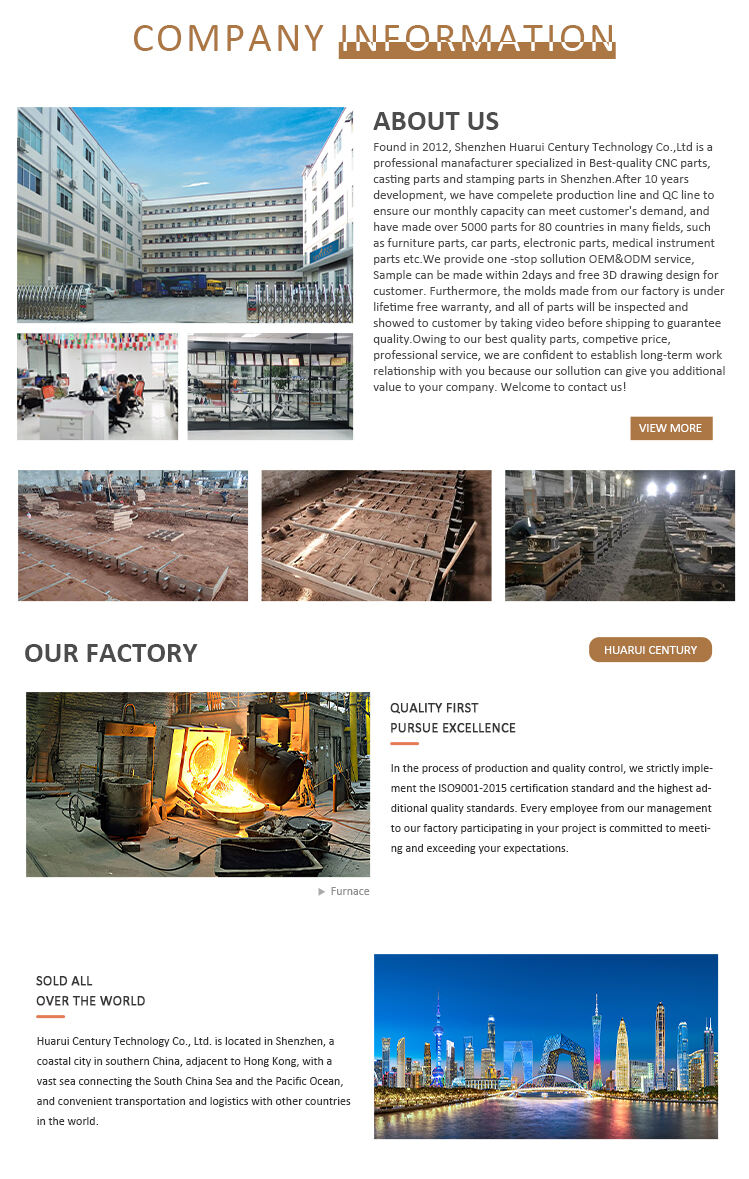

Our Integrated Service: From Your Blueprint to Finished Part

We operate as your seamless extension, offering a comprehensive, integrated service that transforms your concept into a high-quality, market-ready component. Our process begins with your design, and we support all major file formats including IGES, STEP, and Solidworks. Our engineering team conducts a thorough design-for-manufacturability analysis, providing expert feedback to optimize your part for the die casting process, potentially enhancing performance and reducing costs. We then move to precision mold making, utilizing high-grade steels to ensure longevity and consistency throughout the production cycle.

The journey continues with controlled die casting production, followed by our in-house surface treatment and any necessary secondary machining, all under one roof. This vertical integration guarantees strict quality control at every stage, streamlined communication, and significantly reduced lead times. We are not just a parts supplier; we are a manufacturing partner based in China, committed to transparency, reliability, and building long-term relationships. Our sales and project management teams are dedicated to understanding your needs and delivering solutions that enhance your supply chain.

Why Partner with Us for Your Die Casting Needs

Selecting the right die casting partner is a critical business decision. We distinguish ourselves through a steadfast commitment to quality, evidenced by our precise control over the entire ADC12 die casting process. Our investment in advanced surface treatment technologies means we deliver parts that are not only dimensionally accurate but also finished to the highest standards for both performance and appearance. We understand the global market's demand for flexibility, offering scalable production from prototyping to full-scale manufacturing runs with consistent results. Our approach is collaborative; we view each project as a partnership, working closely with you to solve challenges and achieve optimal outcomes. By choosing our die casting service, you gain more than a component—you gain a competitive advantage through improved product quality, durability, and aesthetic value. Contact us today to discuss your specific project requirements and discover how our custom ADC12 aluminum die casting parts can elevate your next product.