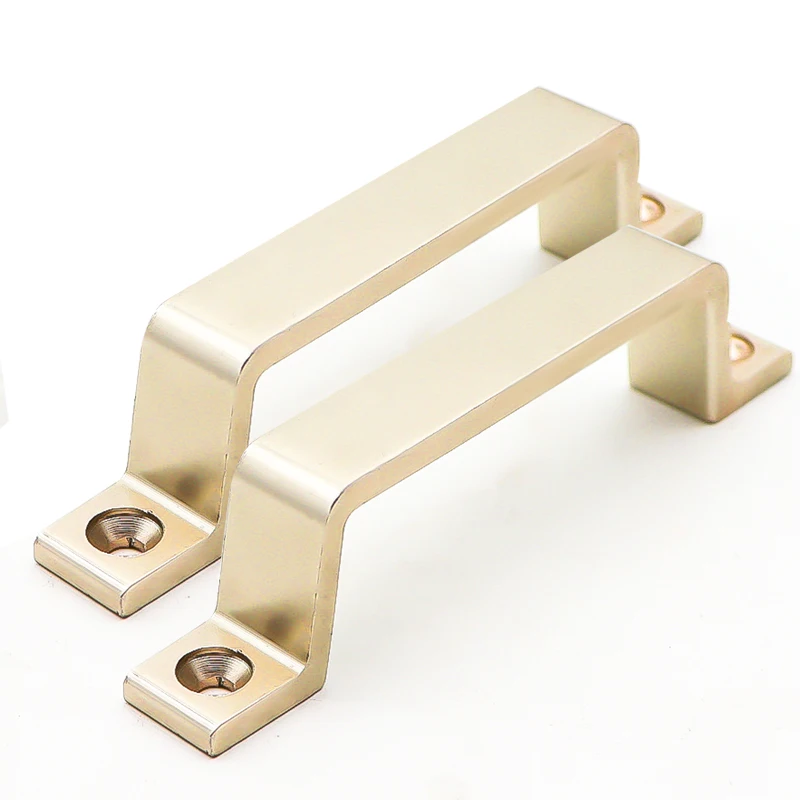

Precision Stainless Steel CNC Machining 304 316 17-4PH Custom Corrosion Resistant Parts

Master the challenges of stainless steel with our dedicated high-precision CNC machining service. We specialize in transforming grades like 304, 316(L), and 17-4PH into complex, durable components that meet tolerances within ±0.01mm. Our expertise lies in overcoming work hardening and thermal distortion through optimized tooling and processes, delivering not just machined parts but complete solutions including critical surface finishes like passivation and electropolishing. Backed by ISO-certified quality control, full in-house capabilities, and deep experience across medical, aerospace, food processing, and industrial applications, we ensure your stainless steel parts are built for performance, longevity, and compliance.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

You are very welcome to visit us among many suppliers

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

Stainless steel is the material of choice where strength, hygiene, and unwavering resistance to corrosion are paramount. However, its very properties that make it indispensable also present significant manufacturing hurdles—work hardening, tool wear, and thermal distortion. Navigating these challenges requires more than standard machining; it demands specialized knowledge and a disciplined process. Our precision stainless steel CNC machining service is engineered specifically for this purpose. We combine advanced technology with deep material science understanding to machine grades from 304 to 17-4PH into reliable, high-tolerance components. When you require CNC machining stainless steel parts that perform flawlessly in demanding environments, from saline atmospheres to sterile cleanrooms, partnering with an expert is not an option—it’s a necessity for success.

Decoding the Alloy: Selecting the Right Stainless Steel for Your Application

The first step to a successful project is choosing the appropriate alloy. Each grade offers a distinct balance of machinability, strength, and corrosion resistance. We guide you through this critical selection. Austenitic grades like 304 and 316(L) are the most common, offering excellent general corrosion resistance and formability; 316L, with its lower carbon content, is essential for welding and superior resistance to chlorides. Martensitic and precipitation-hardening grades like 17-4PH provide dramatically higher strength and hardness, ideal for structural aerospace components or high-wear industrial parts, though they require precise heat treatment control. Our expertise ensures the material selected not only meets your performance criteria but is also optimally suited for efficient, high-quality stainless steel CNC machining, preventing costly errors and rework from the outset.

Conquering the Hard Stuff: Our Process for Predictable, High-Quality Results

Machining stainless steel predictably requires a strategic approach to counteract its inherent challenges. We have developed a proprietary methodology that ensures consistency and quality. To combat work hardening, we employ sharp, specialized tooling with advanced coatings and maintain optimal chip loads to prevent excessive heat and material “rubbing.” Our programmers strategically plan tool paths and sequencing to manage internal stresses, a critical factor for maintaining the dimensional stability of thin-walled or complex geometries. Furthermore, our one-stop processing capability is vital. A component can move seamlessly from precision milling and turning to essential secondary operations like precision grinding and EDM wire cutting for intricate details, all under one roof. This integrated approach minimizes handling, reduces lead times, and gives us complete control over the final quality of your custom stainless components.

Beyond Machining: The Critical Role of Surface Integrity and Finishing

For stainless steel, the machining process is only half the story. Its legendary corrosion resistance is only fully realized with a proper, uncontaminated surface finish. We provide a comprehensive suite of surface treatments tailored to your part’s function. Passivation is a fundamental chemical process we perform to remove free iron particles and enhance the natural chromium oxide layer, maximizing corrosion resistance. For applications demanding ultra-smooth, easy-to-clean, and hygienic surfaces—such as in medical devices or food processing equipment—we offer electropolishing. This electrochemical process uniformly removes a microscopic layer, yielding a brilliant, deburred surface that further resists bacterial adhesion and corrosion. By offering these finishes in-house, we guarantee a seamless transition from machining to a fully finished, performance-ready part.

Where Precision Meets Pragmatism: Industry-Specific Applications

Our stainless steel CNC machining expertise is applied to solve real-world problems across critical industries. In medical and life sciences, we machine biocompatible 316L components for surgical instruments, implant prototypes, and diagnostic equipment, adhering to stringent cleanliness protocols and achieving the specific surface finishes required for sterilization. The aerospace and defense sectors rely on us for high-strength, lightweight 17-4PH brackets, fittings, and engine components that must perform under extreme stress and temperature fluctuations. For food, beverage, and pharmaceutical applications, we produce 304 and 316 parts for valves, pump housings, and mixing assemblies, with finishes that meet USDA and FDA guidelines for cleanability and safety. This cross-industry experience means we understand not just how to machine a part, but why its material and finish are critical to your system’s overall reliability and compliance.

The Foundation of Trust: A Quality System Built on Verification

In high-stakes applications, confidence in your supplier’s quality is non-negotiable. Our entire operation is structured around our ISO 9001 certified quality management system, ensuring traceability and control at every step. For stainless steel parts, our inspection regimen is particularly rigorous. We utilize Coordinate Measuring Machines (CMM) to verify complex geometries against your 3D model, ensuring adherence to the ±0.01mm tolerance. We also employ surface roughness testers to validate finish specifications (Ra values) critical for corrosion and cleanability performance. Every shipment is accompanied by a detailed inspection report, and we champion transparency through virtual factory tours, allowing you to audit our processes remotely. This unwavering commitment to measurable, documented quality transforms a simple purchase into a secure, long-term technical partnership.

From Blueprint to Benchmarked Part: Our Streamlined Collaboration Process

Initiating a project for critical stainless steel components should be a clear, collaborative, and efficient process. Ours is designed to be just that. It begins with you sharing your CAD files and requirements. Our engineering team then conducts a complimentary, in-depth Design for Manufacturability (DFM) analysis, providing expert recommendations to optimize your design for both performance and cost-effective CNC machining. You will receive a comprehensive, transparent quotation shortly thereafter. Upon project approval, a dedicated project manager becomes your single point of contact, overseeing production and providing regular updates. With our 24-hour online service and support for multiple global logistics options, we ensure a smooth journey from concept to delivery. We aim to be more than a vendor; we strive to be a reliable extension of your engineering team, delivering the high-quality, corrosion-resistant stainless steel parts that form the backbone of your most important products.