5-Axis CNC Design & Machining for Complex Aluminum Stainless Steel Parts

Transform ambitious concepts into production-ready reality with our integrated 5-axis CNC design and machining service. We specialize in manufacturing complex, high-precision components from both aluminum and stainless steel, offering expert Design for Manufacturability (DFM) analysis to optimize your parts for superior performance and cost-effectiveness. From a single prototype delivered in 3-7 days to production runs, our advanced multi-axis capabilities ensure unparalleled geometric freedom and accuracy. Leverage our expertise as a Shenzhen-based manufacturer to streamline your development cycle, reduce risk, and bring innovative aluminum and stainless steel parts to market faster.

| Material: | Iron,Zn Alloy,Aluminum Alloy,Stainless steel,Aluminum | |||||||

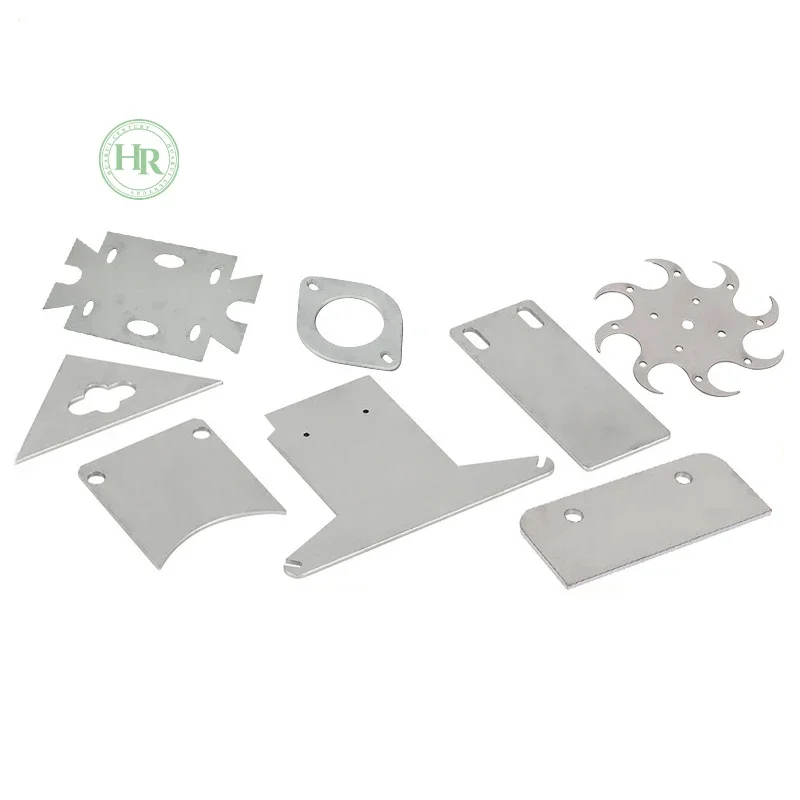

| Process: | Die casting,lathe,spring,cnc,stamping | |||||||

| OEM: | Available | |||||||

| MOQ: | 1Pcs | |||||||

| Mass lead time: | 15-20Days | |||||||

| Sample time: | 3-7Days | |||||||

| Payment terms: | T/T, L/C, Money Gram, PayPal, Crash, Western Union | |||||||

| Country of origin: | Shenzhen, China | |||||||

FAQ

Q: Does your company belong to a manufacturing company or a trading company?

A: We are industrial component manufacturing company.

Q: What is your company's R / D ability?

A: We have a 10-persons R&D department responding for the design of a mold or production technology

Q: What is the quality control of your company?

A: Our company has the system certification of ISO9001 and IATF16949. We have special product laboratory and measurement room, and have very professional testing & measuring equipment. We do raw material incoming inspection, in-process product quality control and outgoing goods quality control.

Q: How long will the quotation be completed normally in your company?

A: According to different products, consider whether the common materials used and how the processing precision, and in general,the quotation will be completed in 1-2 days.

Q: What is lead time for goods delivery normally?

A: Depends on different product type, the delivery lead time will be 5 to 15 days normally after PO confirmed.

In the pursuit of innovation, the most groundbreaking product designs are often constrained not by imagination, but by the limitations of conventional manufacturing. Complex geometries, lightweight structures, and demanding material requirements for aluminum and stainless steel parts can stall even the most promising projects. Our service is engineered to break these constraints. We offer more than machining; we provide a collaborative partnership rooted in 5-axis CNC design and machining. By integrating expert manufacturability analysis at the design phase with state-of-the-art multi-axis execution, we ensure your most sophisticated concepts for aluminum parts and stainless steel parts are not only viable but optimized for performance, reliability, and efficient production from the very start.

Designing for Reality: The Strategic Value of Early Manufacturing Insight

A design confined to a screen is a hypothesis. Its true test is manufacturability. This is where our CNC machining design service provides critical strategic value. Our engineers act as an extension of your team, conducting in-depth Design for Manufacturability (DFM) reviews on your 3D models. We analyze your part with the mindset of the 5-axis machine, identifying potential issues such as inaccessible features for cutting tools, excessive thin walls prone to distortion in stainless steel, or inefficient material use in aluminum components that could increase cost and weight. We provide actionable feedback—suggesting draft angles, optimizing internal radii, or recommending material alternatives—to transform your design into a model of manufacturing efficiency without compromising its intent. This proactive collaboration mitigates risk, avoids costly mid-stream redesigns, and significantly shortens your time-to-market.

Mastering Two Material Worlds: Aluminum and Stainless Steel on One Platform

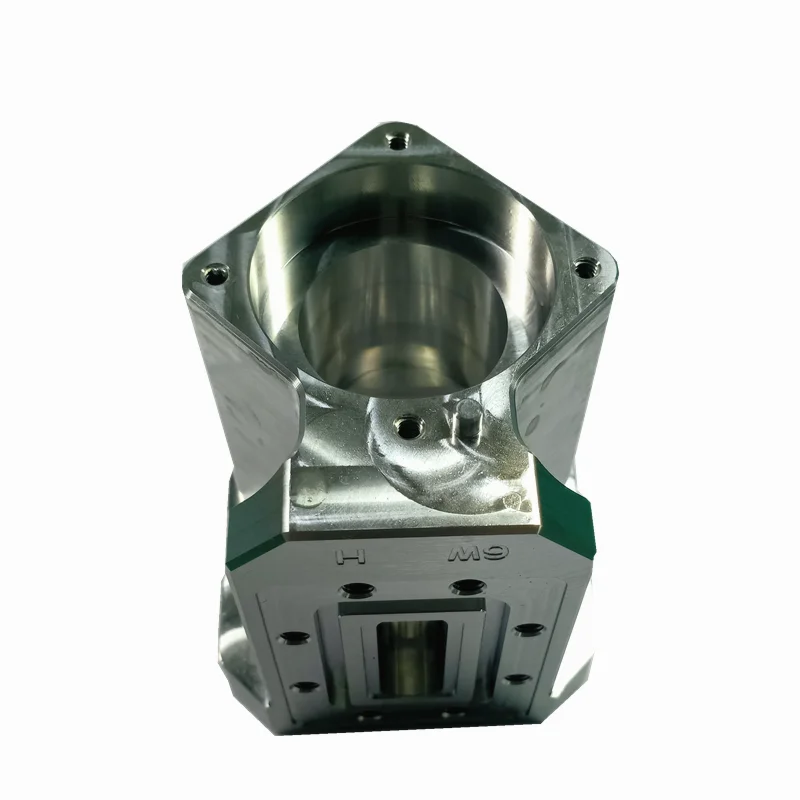

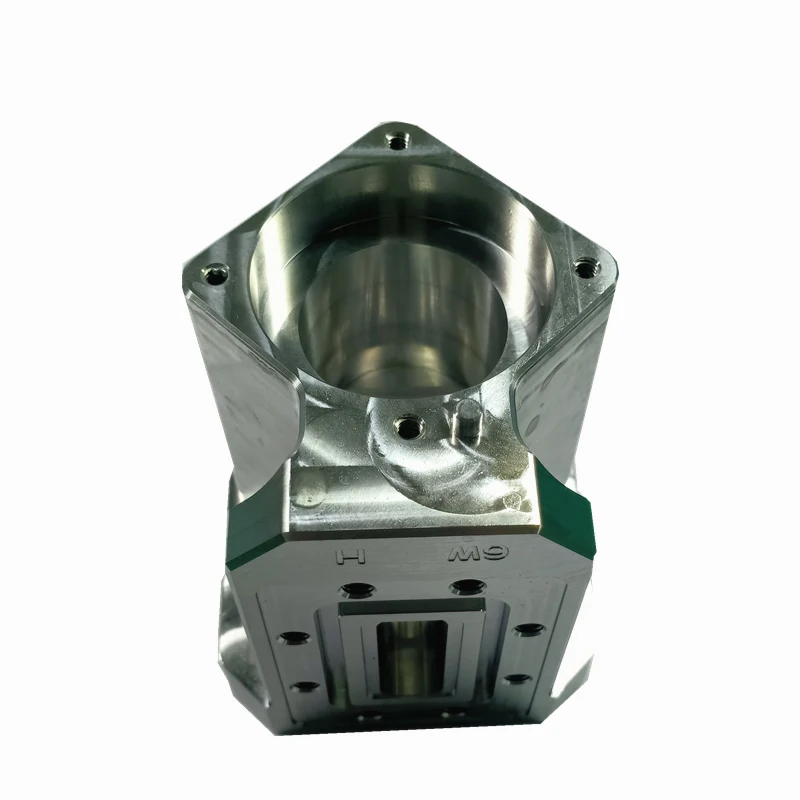

The choice between aluminum and stainless steel is fundamental, driven by application needs for weight, strength, or corrosion resistance. Our expertise lies in mastering both on our advanced 5-axis machining platforms. For aluminum CNC components, we leverage high-speed machining strategies to achieve exceptional surface finishes and rapid material removal, perfect for creating lightweight, structurally efficient parts like aerospace brackets or heat-dissipating enclosures. Conversely, machining stainless steel demands a different approach to manage its toughness and work-hardening tendencies. We employ rigid tooling, specialized cutting parameters, and precise thermal control to maintain accuracy and tool life, producing durable, corrosion-resistant parts such as complex valve bodies or medical instrument housings. This dual mastery ensures that material selection is driven purely by your product's requirements, not by our manufacturing limitations.

The 5-Axis Advantage: Unlocking Geometries Beyond 3D

Why is 5-axis machining the cornerstone of this service? Because it redefines what is possible. Unlike 3-axis machining, a 5-axis system can rotate the cutting tool or workpiece dynamically, allowing the tool to approach the material from virtually any angle in a single setup. This capability is transformative. It allows for the monolithic machining of parts with complex undercuts, deep cavities, and compound curved surfaces that would otherwise require multiple fixtures and assemblies. For an aluminum aerodynamic component, this means smoother contours and enhanced integrity. For a stainless steel surgical tool with intricate internal channels, it guarantees precision and cleanliness. This single-setup philosophy is key to achieving the exceptional accuracy and superb surface quality that define high-performance components, while also reducing lead times by minimizing manual intervention and refixturing.

From One to Many: A Prototype-to-Production Pipeline Built for Speed

Innovation demands agility. Our service structure is designed to support your entire product lifecycle with remarkable responsiveness. We champion rapid validation with a 1-piece MOQ and a 3 to 7-day sample lead time for 5-axis machined prototypes. This allows you to physically test, fit, and function-check a complex design in the intended material with minimal upfront investment and delay. Once the design is verified, our scalable manufacturing processes ensure a seamless transition to higher-volume production, with mass production lead times as short as 15-20 days. This seamless pipeline, managed under one roof, eliminates the friction and requalification hurdles of switching suppliers, providing a streamlined, dependable path from concept to commercial reality.

Applications Engineered for Excellence

Our integrated design and 5-axis machining service drives innovation across high-tech industries. In aerospace and robotics, we produce strong, lightweight aluminum frames and durable stainless steel actuator components that withstand extreme forces. The medical and dental field relies on us for biocompatible stainless steel instrument bodies and custom aluminum device housings that meet stringent regulatory standards. For semiconductor and energy equipment, we manufacture complex, ultra-clean aluminum vacuum chambers and corrosion-resistant stainless steel fluidic manifolds. This broad application experience informs our DFM process, ensuring we understand the critical performance and compliance needs your parts must satisfy in their end-use environment.

The Foundation of Trust: Quality and Transparency in Every Step

Precision manufacturing requires unwavering commitment to quality. Our processes are governed by a robust quality management system, ensuring consistency and traceability. We utilize advanced CNC machining technology capable of holding tight tolerances, and every part undergoes rigorous inspection. For international clients, we simplify collaboration: based in Shenzhen, China, the heart of global advanced manufacturing, we offer multiple convenient payment terms including T/T, L/C, and PayPal. We provide clear communication at every stage, from initial DFM consultation to regular production updates, building a partnership based on transparency, reliability, and mutual success.

Your Next Step: Partner with a Manufacturing Innovator

Beginning a project with a true manufacturing partner should be straightforward. Share your design aspirations, sketches, or CAD files with our team. We will initiate a technical consultation to understand your goals and challenges. Following this, you will receive a comprehensive proposal that includes our DFM insights, a recommended manufacturing strategy for your aluminum or stainless steel parts, and a clear, competitive quotation. Upon your approval, a dedicated project manager oversees all aspects of execution. As your partner in innovation, we are committed to providing the technical expertise, advanced 5-axis CNC capability, and responsive service needed to transform your most challenging designs into market-leading products.