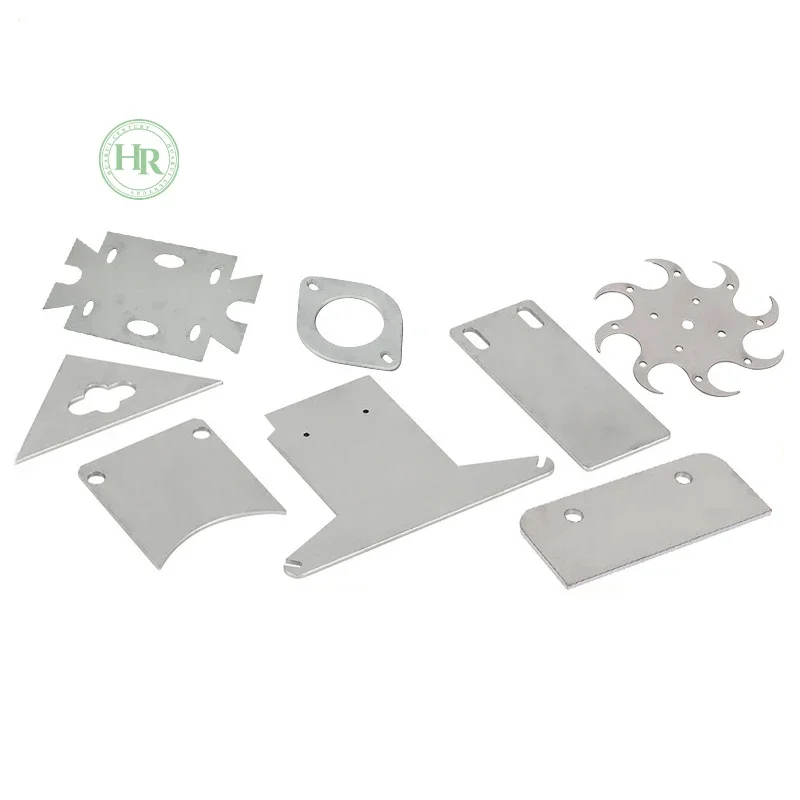

Precision Steel Gears Racks Pinions Custom CNC Machining OEM Transmission Parts

Engineer reliable motion with our custom CNC machined steel gears, racks, and pinions. We specialize in manufacturing high-precision, flexible transmission components tailored to your exact specifications—module, pressure angle, and face width. Utilizing advanced CNC machining and expert heat treatment, we ensure optimal strength, wear resistance, and quiet operation for demanding applications in automation, robotics, machinery, and beyond. Our integrated process, from material selection to final grinding, guarantees exceptional accuracy and longevity. As experienced China-based manufacturers, we offer a dependable single-source solution for prototyping and production of critical drive components.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

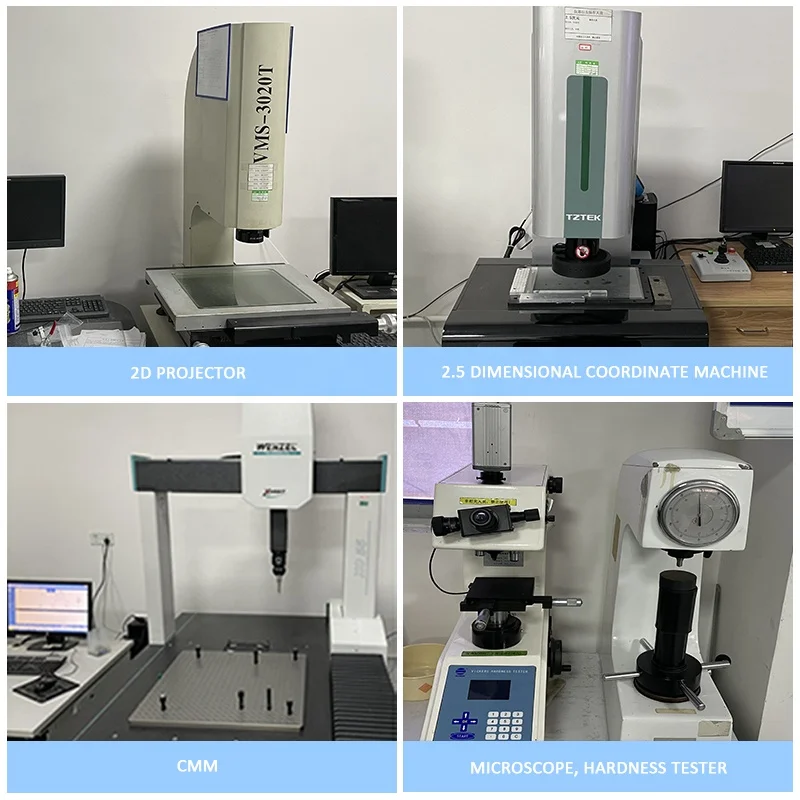

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

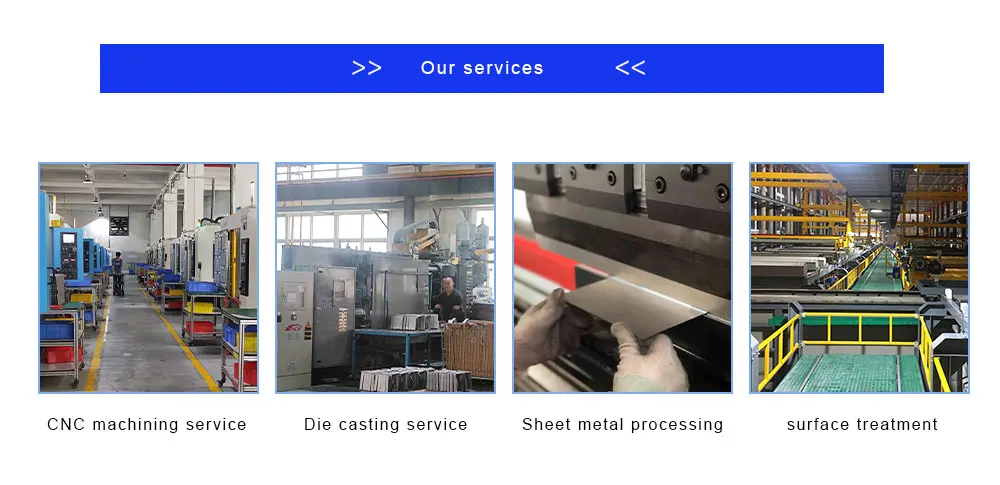

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

You are very welcome to visit us among many suppliers

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

In any mechanical system where precise motion, power transmission, and positional accuracy are paramount, the quality of the gears, racks, and pinions is non-negotiable. These components form the essential language of machinery, translating rotational force into linear motion or speed changes with unwavering reliability. Our specialized service is dedicated to mastering this language. As expert manufacturers, we provide custom CNC machining for high-precision steel gears, gear racks, and pinions. We understand that off-the-shelf solutions often fall short, which is why we focus on delivering flexible, application-specific transmission parts that are engineered from the ground up for performance, durability, and seamless integration into your designs.

Material Science in Motion: Selecting the Right Steel for Strength and Longevity

The journey to a superior gear begins long before machining, with the critical choice of material. Not all steel is created equal for transmission duties. We guide you through this selection to match your operational demands. For high-strength, core-tough applications, we recommend and process alloy steels like 4140 or 4340, which can be through-hardened. Where exceptional surface hardness and a tough core are needed to withstand repeated impact and wear—such as in heavy-duty pinions—we utilize carburizing grades like 8620. For corrosive environments, stainless steel options are available. Our expertise ensures the base material provides the ideal foundation for subsequent machining and heat treatment, directly impacting the final component's load capacity, fatigue life, and resistance to failure.

Precision in Every Tooth: The CNC Machining Artistry Behind Flawless Gears

Creating a gear that runs smoothly, quietly, and efficiently is an exercise in extreme precision. Our custom CNC machining process is meticulously calibrated for this task. Using state-of-the-art CNC milling centers and gear-specific cutting tools, we translate your digital parameters—module, number of teeth, pressure angle, and helix angle—into physically perfect tooth profiles. For spur and helical gears, our advanced programming ensures exceptional profile and lead accuracy. For racks, we achieve consistent, linear tooth spacing over extended lengths, which is critical for precise linear motion. This level of control during the initial machining phase is what sets the stage for a high-performance transmission component, ensuring that every tooth engages as designed, minimizing backlash and maximizing efficiency.

Beyond Machining: Heat Treatment for Unmatched Durability and Performance

A machined gear is only partially complete. To survive the harsh realities of continuous meshing and load transfer, it must be hardened. Our integrated service includes critical heat treatment processes tailored to the gear's function. Through-hardening provides uniform strength for components subjected to high torsional stresses. For gears and pinions requiring extreme surface hardness to resist pitting and wear while maintaining a shock-absorbent core, we perform precision carburizing or induction hardening. We closely manage these processes to minimize distortion, a common pitfall that can ruin precision-machined profiles. Following hardening, we often employ finishing processes like precision grinding or honing to correct microscopic distortions and achieve the final, ultra-smooth tooth surface that ensures quiet operation and extended service life.

Ensuring Perfect Mesh: Our Rigorous Quality Assurance Protocol

The true test of any custom gear or rack is how well it meshes with its mating part. Our commitment to quality extends to verifying this interaction. We employ specialized metrology, including gear inspection instruments, to measure critical parameters such as tooth profile error, pitch deviation, and runout. This data-driven approach guarantees that every custom steel gear or rack we produce not only meets the dimensional print but also performs its functional role flawlessly. Our standard tolerance for critical non-form features is ±0.01mm, and our 100% quality inspection before delivery includes checks on these vital transmission characteristics. We provide detailed inspection reports, giving you documented confidence in the precision and reliability of the components that will drive your machinery.

Application Engineering: Powering Innovation Across Industries

Our custom transmission components are the driving force behind a wide array of advanced machinery. In industrial automation and robotics, our precision racks and pinions enable accurate linear positioning in gantry systems and robotic arms. For the machine tool industry, we manufacture durable gear trains and drive components that withstand high loads and ensure machining accuracy. The medical and packaging equipment sectors rely on our custom gears for smooth, reliable motion in sensitive and high-cycle applications. Even in transportation and heavy equipment, our robust gears and pinions play a critical role. This diverse experience allows us to understand the unique challenges of your industry and recommend the optimal design and material solution for your specific gear, rack, and pinion needs.

The Strategic Advantage of a Dedicated Transmission Parts Partner

Choosing a specialist manufacturer for your custom gears and racks offers significant advantages over sourcing from general machine shops or standard catalogs. We provide a consultative partnership, offering insights on design for manufacturability (DFM) to optimize your gear geometry for performance and cost. Our vertical integration—machining, heat treatment, and finishing under one roof—ensures seamless workflow, superior quality control, and shorter lead times. As a China-based manufacturer, we combine this technical expertise with competitive pricing and scalable production capacity, making us a strategic, value-driven source for both prototype development and ongoing production requirements. We become an extension of your engineering team, dedicated to the success of your motion control systems.

Initiating Your Custom Gear Project: A Collaborative and Transparent Process

Starting a project with a trusted transmission component manufacturer is designed to be straightforward. Simply provide us with your gear drawings, specifications, or even a sample of a part that needs replacing. Our engineering team will promptly review your requirements and engage in a technical discussion to confirm all critical parameters. We will then provide a comprehensive quotation detailing the manufacturing process, material recommendation, and timeline. Upon order approval, a dedicated project manager oversees your order through every step, providing updates as needed. Supported by our efficient global logistics, we ensure your custom CNC machined gears, racks, and pinions are delivered reliably, helping you keep your operations—and your products—in smooth, uninterrupted motion.