Hunting For CNC Turning Service Kids?

Do you have any idea how things get so perfectly manufactured? That's where a service for CNC turning can really save you. A service based on doing everything as accurately and with less errors is possible so that the final products came out very cool. CAD, which stands for computer-aided design allows the parts to be made in a perfect manner thus thanks to innovative technology. CNC (Computer Numerical Control) is the newest and most accurate form of item production.

In this article, we are going to discuss why it makes sense to avail of a CNC turning service compared with the older methods of actual manufacturing. Firstly, it's super fast! CNC works in minutes, whereas traditional methods used to take hours. This quick custom machining service makes CNC turning suitable for a variety of companies because it takes less time to produce parts. The next big benefit is its accuracy. Every part is made perfectly, through the use of computer programs that guide how the machine will move and so allows no human failure. In addition to these features, CNC machines can achieve complex precision cuts and shapes which were impossible with ordinary traditional tools.

CNC Turning is in the step forward with further progression of technology. Technological advances in software also enhance the accuracy of measurements and speed up data collection. On another note, CAD software provides designers with incredible flexibility to design sophisticated components which can be reproduced accurately by CNC turning machines.

Safety in operating CNC machines is the number one point. The officials are also experienced institutions in the operation, which follow safety protocols to ensure appropriate use of these machines. The chance of accidents or hazards is minimum as they able to work by automating the process, which offers security in turning CNC.

The functionality of the CNC Turning in varied industries

In some of the major industries like aerospace, automotive and medical fields; CNC turning machines are crucial. They provide professionals and exact parts that your field of industrialist must have. CNC Turning is also used in the production of custom parts, prototypes and short runs.

A Comprehensive Manual on CNC Turning Service

The use of it is very easy, there are a few steps that you need to follow while using CNC turning Service. The program next enters a CAD design file which is then inputted into the CNC turning machine. After the workpiece is placed in a vice, and specialized cutting tools are mounted on the machine. The computer controls the cutting tools to tell them how to make the parts exactly as you specify.

What Do CNC Turning Providers Produce?

This versatile operation can be tailored to the exact component for machining, and there are providers of CNC turning services that provide a broad array of solutions. This allows them to work with different materials including aluminum, steel and plastics.

CNC turning machines ensure higher standard of quality while producing more identically sized product than other traditional manufacturing process. These are machines capable of generating parts with a precision which would otherwise be impossible to achieve by means of manual machining techniques. In the production, quality control measures have been taken all parts should be made according to plan.

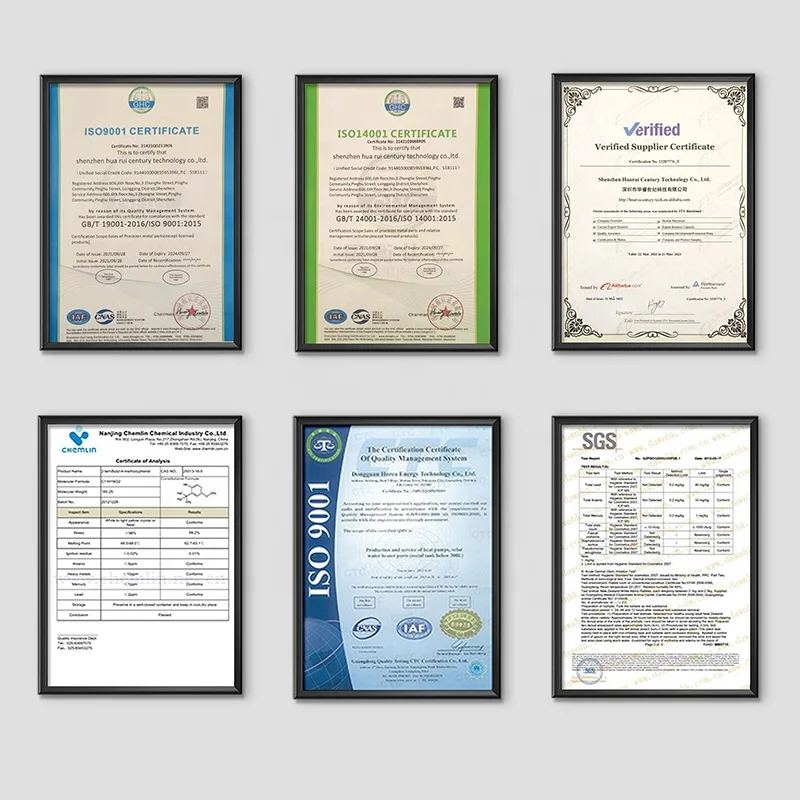

S0 1 40 0 1 certificates, all components be examined and shown customers through video prior shipment to ensure quality. The company been praised widely its Cnc turning service customer satisfaction quality control.

The company provides a range of delivery methods its customers, including express, air, land well as sea Cnc turning service. Products are exported customers in North America, South America, Europe, Middle East, Asia, Africa well as other regions and countries.

The largest products regarding the ongoing company are precision Cnc turning service machined castings, section as well since sheet metal processing. Provide solution which was one-stop and ODM service. OQ 1 sample, produced in 2 days, and free 3D drawings for customers. An eternity is offered by the free factory on every mold.

The organization has over 10 years of many years of OEM experience. It also has a manufacturing that was quality control complete line. Cnc turning service customized metals parts can be found in a range of categories like furniture, auto components, electronic components, medical equipment etc. In addition, it is able to ensure accuracy and efficiency, but make CNC processing casting parts, casting elements along with sheet metal processing that meet or surpass the expectations of the client.

CNC turning machines are used for various applications, such as producing molds and customized parts to manufacturing engine components. The use of this cutting-edge technology is what allows for tailor-made parts that comply with high-level requirements to be produced. Because CNC machines are so versatile and accurate, they can be used effectively to produce a huge variety of parts, prototypes (1 off's) & small batch production. These advantages offered by the CNC turning service are some of the reasons why we see a sharp increase in demand for high technology today. Blessing businesses with a stable, economical and protected manufacturing capability, it enables an open door for customized part production.