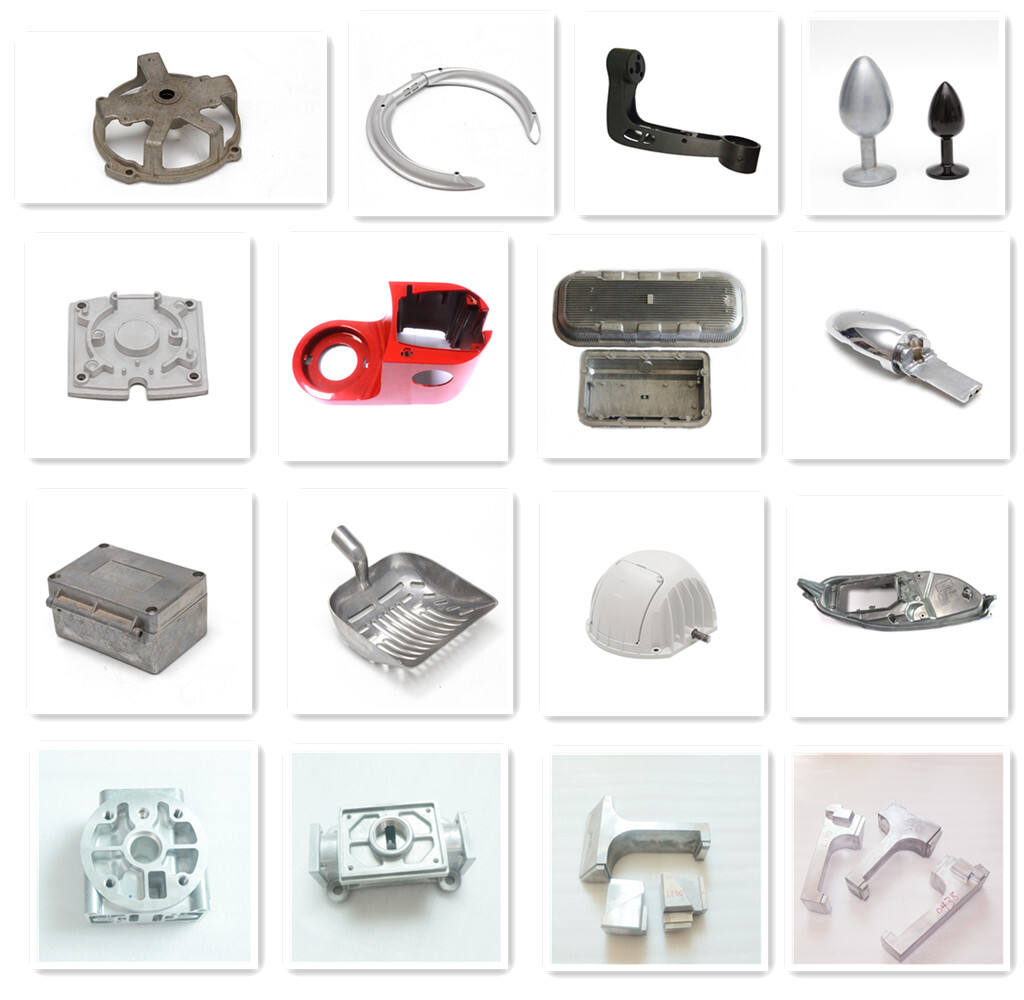

China foundry manufacturers precision custom oem cast iron part zinc metal aluminum die casting parts services die cast aluminum

| Craft name | Die casting parts service |

| Mold Material | Aluminum,SKD61,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

| Material | Aluminum:ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized . |

| Zinc: ZA3#, ZA5#, ZA8# or customized . | |

| Magnesium: AZ91D, AM60B or customized . | |

| Surface Treatment | Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

| Drawing format | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Application | furniture,Industry fittings and Construction and Decoration,etc. |

Product Overview

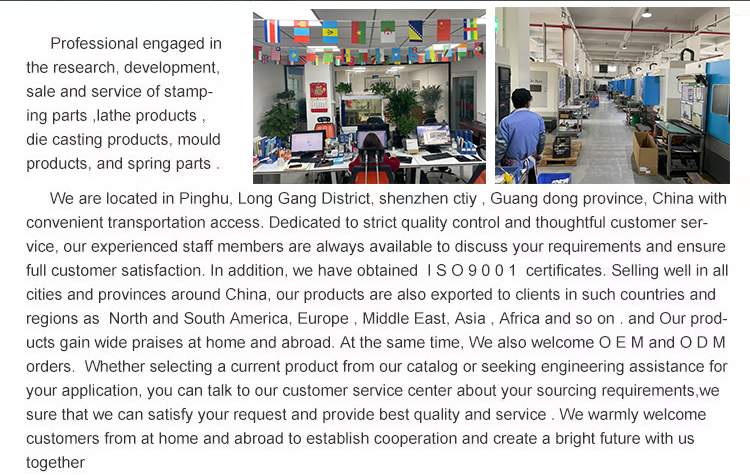

Shenzhen Huarui Century Technology Co., Ltd. offers high-precision, custom OEM die casting services specializing in cast iron, zinc, and aluminum parts. With decades of experience in foundry and casting technology, we provide reliable, large-scale production for industrial, automotive, and consumer electronic applications. Our services include investment casting, sand casting, and die casting, offering both single-piece prototypes and high-volume production.

-

Comprehensive Material Options: We work with a wide range of metals including stainless steel, carbon steel, alloy steel, aluminum alloys, brass, and aluminum bronze to meet diverse functional requirements.

-

High Precision & Stability: Parts are manufactured to strict tolerances, ensuring consistent dimensions across batches, suitable for complex mechanical assemblies or precision components.

-

Surface Finish Excellence: Depending on the production process, surface finishes range from Ra1.6 to Ra3.2μm, ideal for both functional and aesthetic applications.

-

Versatile Applications: Products serve industrial machinery, automotive components, hydraulic and pump systems, construction hardware, marine fittings, and electronics housings.

-

Customization & OEM Services: We accommodate custom designs according to clients’ 3D drawings, including tailored surface treatments, heat treatments, or plating finishes to meet unique specifications.

This combination of material flexibility, precision, and tailored manufacturing ensures our clients receive high-quality, durable, and cost-effective cast components for both standard and specialized requirements.

Product Advantages

Shenzhen Huarui Century Technology Co., Ltd. leverages state-of-the-art die casting technologies to deliver superior parts for a wide range of applications. Below are three key advantages highlighted for their technical and practical significance:

High Production Efficiency and Automation

Our foundry operations incorporate fully automated die casting lines, capable of producing thousands of components per day with minimal manual intervention. This automation ensures fast turnaround times and maintains consistent quality, even for large-scale production runs. Automated processes also reduce human error, lower labor costs, and improve production repeatability.

Near-Net Shape Precision and Low Scrap Rate

Through precise mold design and controlled casting parameters, our die-cast components achieve near-net shapes, drastically reducing post-machining requirements. This capability enhances material utilization, minimizes waste, and allows production of complex geometries with fine details such as embedded threads, ribs, and grooves. High precision casting ensures repeatability across large batches, critical for automotive or industrial assemblies.

Superior Surface Finish and Functional Integrity

Our die casting processes achieve surface finishes of up to Ra1.6μm, providing parts that require minimal post-processing. Combined with high-pressure molding and rapid metal cooling, this ensures excellent mechanical strength and a dense internal structure. Functional elements, such as thin walls (aluminum ≥1.2mm, zinc ≥0.5mm) or heat-dissipating fins for electronic housings, are produced consistently with high durability and aesthetic quality.

Production Process

The die casting production process at Shenzhen Huarui follows a rigorous, step-by-step workflow to ensure product quality, consistency, and timely delivery:

-

Design & Engineering: Begin with client-provided 3D drawings or specifications. Mold design simulations optimize flow channels, cooling paths, and venting to ensure minimal defects.

-

Mold Fabrication: High-precision steel molds are manufactured using CNC machining and surface finishing, capable of millions of cycles for mass production.

-

Casting Operation: Depending on the material, aluminum, zinc, or cast iron is melted and injected under high pressure into molds. Cold-chamber or hot-chamber die casting machines are selected according to alloy type and product size.

-

Post-Casting Processing: Components undergo deburring, trimming, drilling, threading, or other machining as required. Surface treatments such as plating, powder coating, heat treatment, and polishing are applied to meet functional or aesthetic requirements.

-

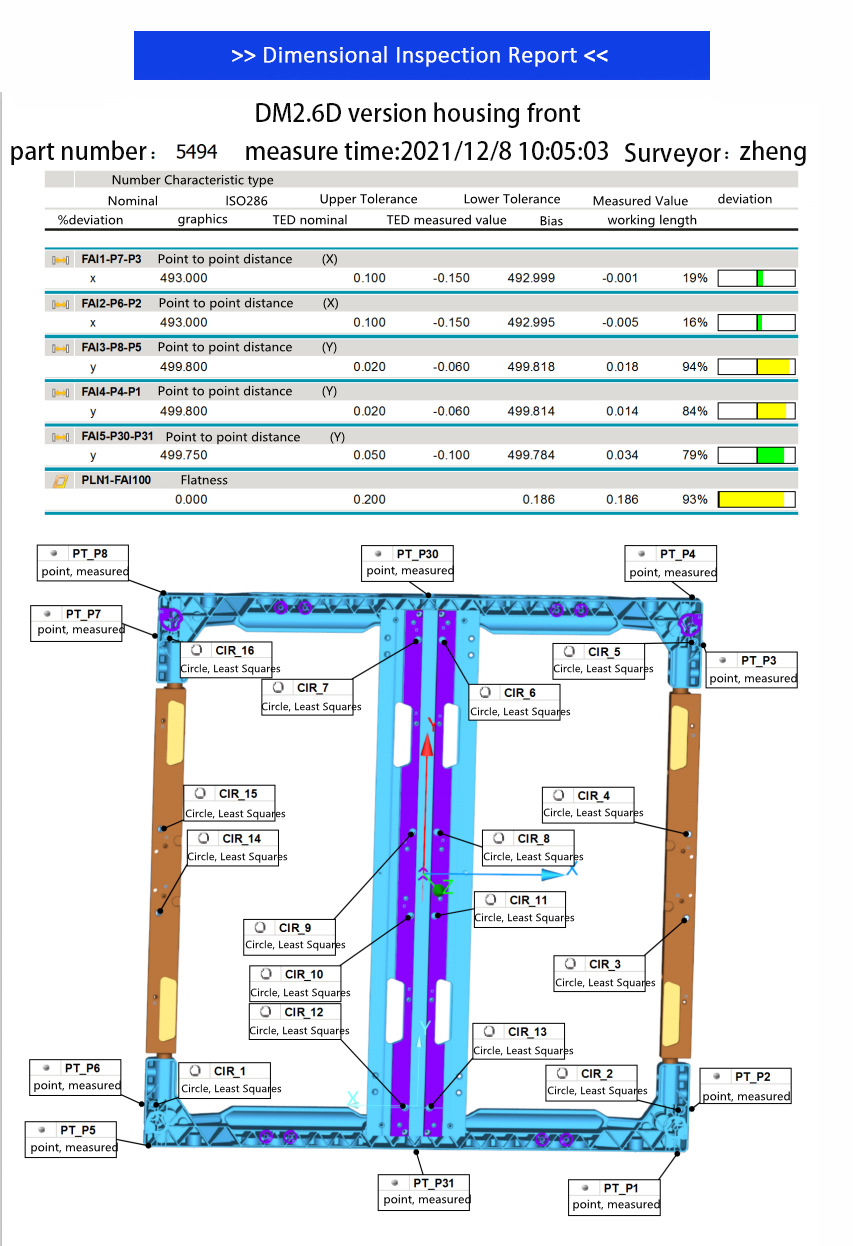

Inspection & Quality Assurance: Each batch is strictly inspected using chemical composition analysis, X-ray radiography, magnetic particle testing, and CMM measurement to ensure compliance with customer specifications.

-

Packaging & Delivery: Finished parts are carefully packaged to prevent damage and shipped according to client requirements, ensuring timely arrival and ready-to-use components.

This structured workflow ensures the highest quality standards while maintaining efficiency and cost-effectiveness.

Product Parameters

| Parameter | Specification / Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HUARUI |

| Model Number | HR |

| Product Name | Die Casting Parts, Sand Casting, Investment Casting |

| Process | Casting, Deburring, Drilling, Threading |

| Certification | ISO9001, TS16949 |

| Service | Customized OEM |

| Size | According to Customer's 3D Drawing |

| Surface Treatment | Customized; Heat Treatment, Polishing, Plating, Machining, Shot/Sand Blasting, Zinc Plating, E-Coating |

| Tolerance | Customer Drawing Request |

| Standard | Client Specification, ISO, DIN, AISI, ASTM, BS, JIS |

| Color | Customized |

| Quality Control | 100% Strict Inspection |

| Surface Finish | Ra1.6 – Ra3.2 μm |

| Maximum Size | ≤1200mm × 800mm × 400mm |

| Weight Range | 0.1 – 120 kg |

| Materials | Stainless Steel, Carbon Steel, Alloy Steel, Aluminum Alloy, Brass (CuZn38, H62), Aluminum Bronze (AB2.863) |

| Applications | Industrial Parts, Machinery Parts, Construction Components, Valves, Pumps, Hydraulic Equipment, Agricultural Machinery, Marine Hardware, Automotive, Electronics |

| Inspection Methods | Spectrum Analysis, Magnetic Particle Inspection, Cleanliness Inspection, X-Ray Radiography, CMM Measurement |

Inquiry Invitation

Shenzhen Huarui Century Technology Co., Ltd. welcomes inquiries for OEM and custom die casting services. Our team is ready to provide free consultation, technical advice, and sample quotations. Submit your 3D drawings or specifications to receive a customized solution, competitive pricing, and a production plan tailored to your requirements.

Contact us today and experience high-quality, precision casting services for your business needs.

FAQ

Q1: What materials can you cast?

A1: We work with stainless steel, carbon steel, alloy steel, aluminum alloys, brass, and aluminum bronze.

Q2: What is the maximum size of a casting?

A2: Maximum casting size is ≤1200mm × 800mm × 400mm.

Q3: Can you provide thin-wall castings?

A3: Yes. Zinc alloys can be cast down to 0.5mm, and aluminum alloys down to 1.2mm.

Q4: What surface finishes are available?

A4: Surface finishes range from Ra1.6 to Ra3.2μm, and additional treatments include heat treatment, plating, polishing, sand blasting, and e-coating.

Q5: Do you provide OEM and custom production?

A5: Yes. We provide full OEM customization, including tailored molds, casting parameters, and post-processing to meet client specifications.

Q6: How do you ensure quality?

A6: We conduct 100% strict inspection using spectrum analysis, X-ray radiography, magnetic particle inspection, and CMM measurements for dimensional accuracy.