Making a decent part begins with a good set of tools and equipment. Huarui'sSpecialrist machines and quality equipment manufacture the isomorphic machined parts to ensure all of our high standard requirements. But it’s not just the tools that matter; the way we use them is critical, too. Each component has to be scrutinised, making sure it is produced accurately and fits precisely.

A common method we use to ensure accuracy of our parts is designing components using computer models known as CAD files. These files are 3D images or representations of the parts that we want to manufacture. This crucial data is utilized for molds creation and parts casting. This ensures that we build parts that will work together when manufactured.

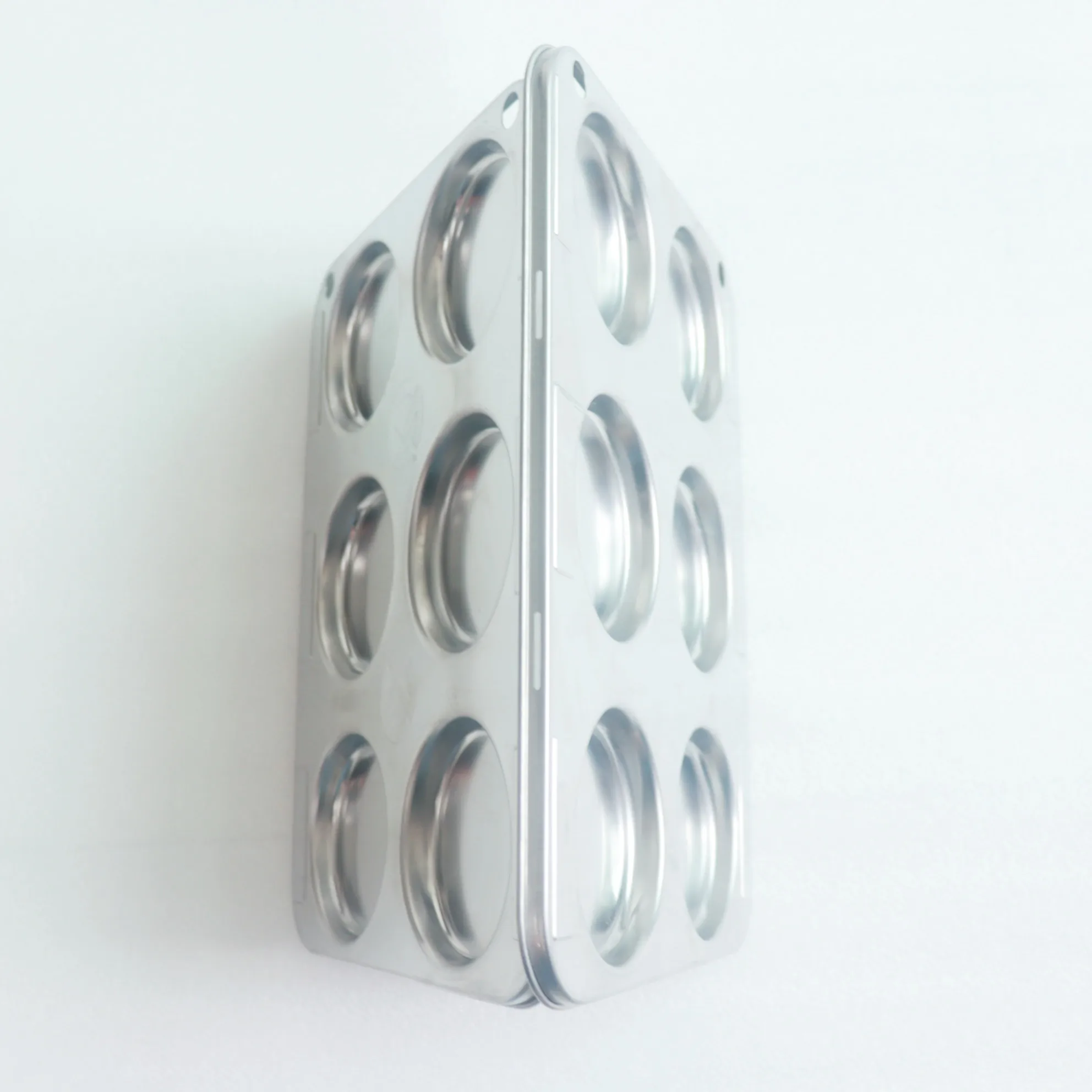

Casting is the process of melting metal and pouring it into a mold, which is a hollow shape that shapes the metal into its final form. Then we take the metal out of the mold when it is cooler and hardened and finish it just like we want it — the exact shape and size we want. Huarui has various methods to cast parts like sand casting, investment casting and die casting.

For sand casting, we use a hot metal and pouring that into a mould in order to get the desired shape. It is commonly used as it is simple and works well. In the case of investment casting, we take wax shapes, build molds out of them, and pour metal into those molds while they are hot. This enables us to produce both highly accurate and properly finished parts, things many applications need.

Simulation is a key enabler to optimize the casting process. We simulate with special software how the hot metal will move when poured in the mold and fills the empty spaces. We can also examine how the metal solidifies and determine if there will be issues like air pockets or cracks that can compromise the part.

Of all the decisions that one can make when constructing parts, selecting the appropriate material is by far the most critical. Cautious consideration to what the metal is capable of doing, will likely function in situations. If we want something to be strong enough to carry the loads we put on it, feet or people; we want something to resist rust and other damage.

Because every project is unique, I don’t think there is one way to cast parts. What process we take varies, based on things like size, complexity, precision and finish. This is why we use several resembling systems, as every one of them has diverse qualities and preferences to adapt to the buyers' prerequisites.

The business has over 10 years of OEM expertise, and it offers a complete production as well as the QC line. We could offer casting parts customized metal in numerous fields, such as furniture parts and auto parts, electronic parts, medical parts... In addition, it's going to it guarantee the efficiency and accuracy of the manufacturing process and produce CNC processing casting, components as well because sheet metal processing, which meet or exceed expectations from the customer.

The company obtained IS 09 00 1 as well has received a lot of praise its casting parts to quality control customer service.

These products that can easily be biggest by the company are precision casting parts machined castings, items of metal too as sheet metal processing. We offer OEM and ODM solutions. OQ for 1 piece, samples are produced in two days and customers can make their very own 3D designs. The factory also provides a full limitless life on every mold.

To enable customers, receive their purchases more quickly conveniently, the company supports sea transportation, land transportation, express delivery, air transportation. Products delivered to customers throughout North America, South America, Europe, the Middle East, Asia, Africa other countries and casting parts.